Production and intralogistics complement each other perfectly and are growing together. What used to be two completely separate areas is now experiencing joint growth thanks to advances in automation and digitalization. Mobile platforms, AGVs and mobile robots are playing an important role here. Our long-time partner, technology expert Asseco CEIT, is using sensor solutions from SICK. CEIT is now once again relying on the safety expertise of SICK for its new AGVs.

Autonomous vehicles from Asseco CEIT – fully equipped with intelligent sensor technology

Asseco CEIT, a.s. is an innovative technology company that offers comprehensive solutions in the areas of technology and process innovation, industrial automation, digitalization and optimization as well as intelligent, in-house logistics. The company has its own research and development center and is dedicated to supporting the productivity, efficiency and increased competitiveness of industrial companies. Asseco CEIT is based in Slovakia and operates with success on a European level. Its customers include large industrial companies, especially in the automotive, mechanical engineering, chemical and electronics industries. Asseco CEIT has been part of the international Asseco Group since 2017.

“Our first automatic AGV devices with SICK components were FTS500 and FTS1300 tractors, which we used at the largest car manufacturer in Slovakia,” says Rastislav Tribula, responsible for research and conceptual design at Asseco CEIT. He adds: “Since then, new, more modern generations of AGVs with contour or laser navigation have been produced. Our excellent cooperation with SICK as well as the quality of the components are the mains reasons why SICK parts can be found in every automatic-intelligent AGV device from Asseco CEIT.”

Safety solutions for AGVs from SICK: Reliable, efficient, with modular expansion

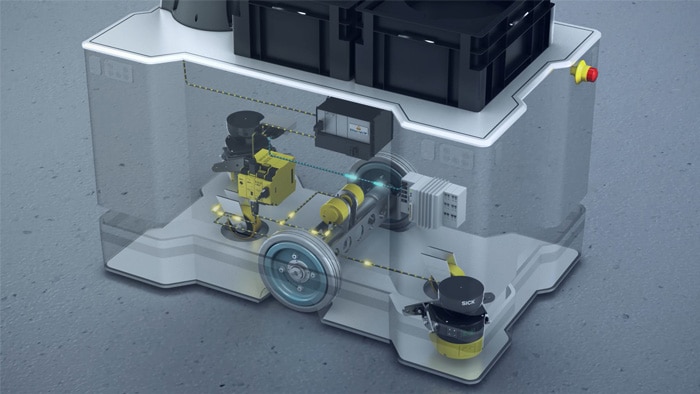

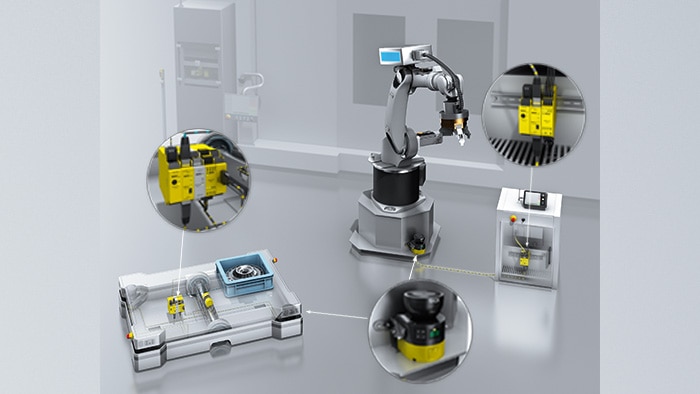

The range of solutions from SICK for mobile platforms enables Asseco CEIT to easily implement line guidance, navigation, positioning and environment perception as well as safety or load handling. From small autonomous transport systems to AGC (automatic guided carts) and specialized AGV (automatic guided vehicle) systems, sensor solutions from SICK cover the entire range of automatically controlled vehicles. The spectrum ranges from cost-effective solutions such as line guidance and simple collision avoidance to fully-certified safety solutions and integrated contour localization.

Intelligent safety system: Fast and secure data exchange with Safe EFI-pro

To protect vehicles using safety laser scanners, the S300 and S300 mini series have already been used in combination with relay modules at Asseco CEIT for many years. Even back then, dynamic signals from the DFS60 incremental encoders were integrated which were used to adapt the monitoring zones of the scanners. Over the years, other anti-collision solutions using 2D LiDAR sensors or 3D machine vision were added to these systems. With the ever-growing market requirements in terms of safety and localization, Asseco CEIT has decided to prepare its portfolio for a new unique solution from SICK: The Safe EFI-pro System safety system combined with the DFS60 incremental encoder and the IME2S non-contact safety switch.

Quick and easy connection of system components in the network

The Safe EFI-pro safety system enables intelligent protection of automatically controlled stackers, robots and other demanding applications. EFI-pro industrial Ethernet-based network technology makes possible the rapid exchange and transmission of secure and non-secure data at all levels of communication. The Safe EFI-pro system combines the modular Flexi Soft safety controller with the microScan3 – EFI-pro safety laser scanner. Secure communication via the EFI-pro communication gateway allows for quick and easy connection of system components in the network.

The innovative safeHDDM® scanning technology gives the microScan3 safety laser scanner outstanding robustness, even in dust or stray light, and provides precise measurement data. Only one device is needed to obtain this measurement data - not only for safety purposes, but also for location and subsequent navigation.

Up to six microScan3 safety laser scanners can be networked for adaptive and safe environmental detection. Each device offers up to eight safety fields to be monitored simultaneously and up to 128 monitoring cases. Together with the Safe Motion Control function of the Flexi Soft safety controller, dynamic adaptation of the monitoring cases to the respective monitored areas is possible, depending on the speed and angle of rotation of the automatically controlled vehicle.

Other new developments and strengthening of innovative power – now and in the future

SICK is working on a number of revolutionary innovations in the field of mobile platforms and is confident that it can continue to be a reliable partner for Asseco CEIT. This concerns not only the field of mobile platforms, but also the production of single-purpose machines, in which Asseco CEIT is also involved. Consultation and training are offered as part of the long-standing cooperation between the two companies. This is what will make it possible for SICK and Asseco CEIT to continue to work together in the future on the development of new solutions.

Read more

Take a load off: optimize loading and displacement by autonomous mobile robots

SICK and SOTO: A new mobile robot for industrial production

No half-measures – Fabmatics and SICK are making mobile robots safe

Ultracompact mobile robots optimize the process chain

Mobilne roboty:

Move into new dimensions

Robotyka staje się mobilna – czy to w produkcji, w logistyce czy też w ramach serwisu. Rozwiązania czujnikowe do wszystkich wariantów robotów mobilnych