Modern logistics processes are a force to be reckoned with: They can handle around 200,000 parcels an hour at one single reloading point. But they are also extremely demanding: They need increased safety for sorting, increased safety for identifying, and increased safety for classifying products. To prevent blockages in the parcel stream, companies have to know how to handle this flow and adapt it. So that warehouse management processes can run smoothly at all times, every single inbound and outbound product has to be recorded correctly. Sensors for identifying objects and measuring volumes are key to ensuring that data in the material flow is reliable. Sensor systems for identifying objects, measuring volumes, and weighing items set a new standard when it comes to flexibility in the logistics industry.

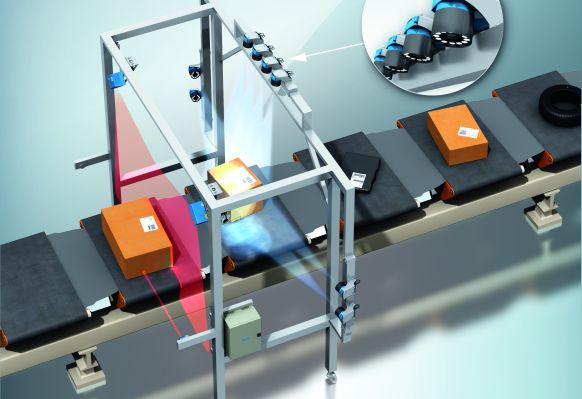

The Lector®65x System offers anything you could ask for: from a simple system to a tailor-made all-in-one solution. The track and trace system based on the Lector®65x matrix camera reliably identifies and decrypts all common types of codes. By integrating SICKs networking concept into the MSC800 network controller, the Lector®65x System can easily be combined with other products, such as ICR8xx line-scanning cameras, volume measurement systems, laser based code readers, or weighing scales. The installation process requires very little time or effort. There is no need to use an external PC. The parameters are configured especially for our customers, the assembly frame is adapted precisely to fit the system in question, and a specialist technician visits the customers site to install all parts of the system.

There is a demand for reliable solutions in all areas of industry

Online trade is booming. An ever-growing number of parcels are shipped every day, making the parcel sorting process more and more difficult. However, this is not the only area of industry looking for extremely efficient solutions. Take companies linked to tires, cars, and automobile parts suppliers for example; or the airport industry; or the food and beverages industry. All of these industries are looking for a safe way to identify products, increase throughputs, and ensure seamless traceability throughout the entire supply chain.

Online trade is booming. An ever-growing number of parcels are shipped every day, making the parcel sorting process more and more difficult. However, this is not the only area of industry looking for extremely efficient solutions. Take companies linked to tires, cars, and automobile parts suppliers for example; or the airport industry; or the food and beverages industry. All of these industries are looking for a safe way to identify products, increase throughputs, and ensure seamless traceability throughout the entire supply chain.

Sorting made easy

Volume measurement system VMS

Volume measurement system VMS

The area of intralogistics is a typical area of application linked to automated sorting processes. However, manual handling and sorting processes can now also be partially automated thanks to the Lector®65x System. Its dynamic focus function can read codes on parcels of all shapes and sizes located on a transport or sorting belt in a mere matter of seconds. The code is twisted? Not a problem. It can also deal with codes covered by a film or located behind an inspection window. Using height information, e.g. from an automation light grid or volume measurement system, the camera can adjust the focus position to fit each object perfectly, thereby maximizing the read rate. In addition to reading the code, the device can also assess its quality. For example, if a faulty label printer causes the no-read rate to rise, the source of the problem is very easy to locate, making it simple to improve the overall process. Any image recorded by the Lector®65x System can be used for video coding and OCR tasks to process additional information on the suppliers label. The VMS volume measurement system provides dimensional data which can be used when streamlining warehouse activities. A scale records the weight during the material flow.

Safe identification

Lector®65x image-based code reader/vision sensor

Lector®65x image-based code reader/vision sensor

In factory automation, code readers live up to their potential in a number of ways, for example by identifying tires or when used for end of line checks in packaging systems. Documenting every stage of the process, they enable users to control processes in full and trace products. Small, dirty, or distorted codes pose a significant challenge to the automotiveand tire industries. The omni-directional image capture and depth of field ensure that markings can be reliably identified in any position and alignment regardless of the tire size. Image-based solutions like the Lector®65x System provide code recognition in many different alignments, even for codes with low bar heights. The Lector®65x System offers even greater modularity and flexibility for designing reading intervals. Depending on the desired field of sight, the system can be expanded to include the necessary number of cameras. The captured images are available as JPG files for analysis, archiving and tracing.

- Productportfolio: Lector®65x System, VMS

- Product video: Lector®65x

- Productportfolio: Track and trace systems