Greater cost-effectiveness through increased productivity - swissQprint is setting a new benchmark with its new Nyala 2 large-format printer. This is also made possible by the machine's smart safety concept, into which SICK's miniTwin2 safety light curtains are integrated, guaranteeing collision-free operation of the print head cartridge.

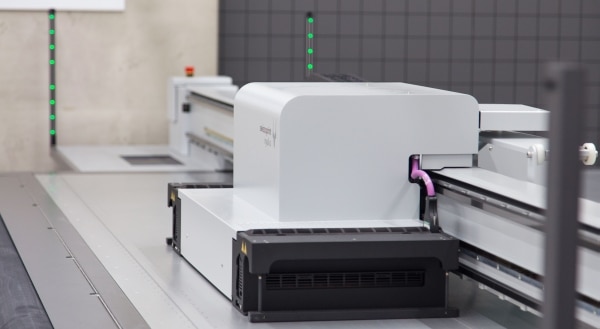

Its high-speed print head cartridge can reach speeds of up to 1.5 m/s, it can print onto up to 206 m² of board or roller conveyors per hour, and in three-shift operation, the unit can print 50,000 m² of material a month - that's more than seven soccer pitches! swissQprint first unveiled the Nyala 2 in May 2014 at the Fespa trade fair in Munich. It boasts a new and enhanced safety concept for industrial large-format printers. SICK's miniTwin2 safety light curtains are an important component of the SwissQprint because not only do they ensure the operator's safety, they also contribute significantly to the printer's availability. The application solution was developed jointly by swissQprint's development team and SICK AG's Industry Account Manager Markus Bühlmann in Stans, Switzerland.

Speed means productivity but demands safety

Nyala 2 large-format printer

Nyala 2 large-format printer

At a size of 3.2 x 2 m, the Nyala 2 flatbed printing table is around 25% larger than the previous model. It is also over twice as fast in certain print modes and still achieves a high-quality print with a resolution of up to 2160 dpi, as demanded by the advertising trade and print industry. All this is made possible by a new generation of print heads. In order to achieve the highest printing performance possible, the print heads can be configured to be always on in tandem mode, if needed. Access to the printing table must not be hindered when inserting and removing plates, but it must also be ensured that operators wishing to directly observe the printing process are protected from injury caused by collisions with the print head assembly. That's why we decided on double-sided protection of the print head for the process and ergonomics-related aspects of the miniTwin2 safety light curtains, says Marc Baumgartner from swissQprint's design team.

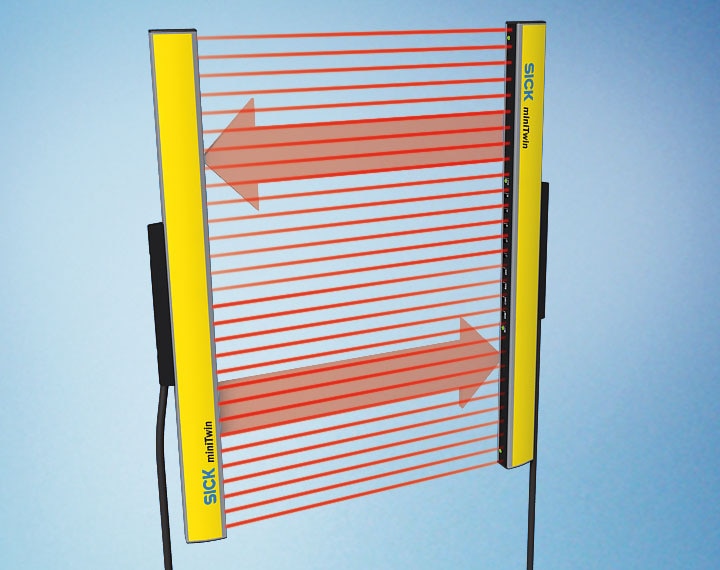

MiniTwin2 safety light curtains

MiniTwin2 safety light curtains

miniTwin2: Safe, compact, easy to integrate

miniTwin2 safety light curtain

miniTwin2 safety light curtain

The safe miniTwin2 safety light curtain conforms to Performance Level PL c as defined in EN ISO 13849-1, or SIL1 as laid out in IEC 61508 and EN 62061. This means the miniTwin2 offers a level of protection that is the result of Nyala 2's risk analysis, says Marc Baumgartner. What makes this contactless protective device so unique compared to competitor's devices is its distinguished design: 'Sender' and 'receiver' components, as well as the equipment for analysis can be found in one, consistently uniform, attractive housing 'stick'. The safety light grid is assembled by turning two miniTwin sticks 180° to face each other, so that the sending and receiving modules are opposite each other. As the curtain housing is very small, we were able to attach the miniTwin2 directly to the pressure beam in a way which saved space and was ergonomic for the operator, adds Marc Baumgartner, explaining how easy it is to integrate the curtain into the larger swissQprint system. Here, the alignment, status and diagnosis displays ensure that operators experience a high level of convenience during start-up. OSSD outputs are integrated directly into the safety controller developed by swissQprint for the large-format printer.

Special solution offers a protective function and avoids waste

Nyala 2's safety concept was designed with two levels. On the first safety level, the miniTwin2 have to detect objects entering the dangerous area of the machine, slow the print head cartridge from its maximum possible speed of 1.5 m/s down to just 0.3 m/s and warn the operator, says Marc Baumgartner. Of particular note here, is that neither the printing process nor printing quality are affected in slow mode, and therefore no waste is produced either. Interruptions and delays impact on our profitability, and avoiding these things makes the Nyala 2 totally unique, says Petra Fetting from swissQprint's Marketing department. The second safety level is activated when a collision occurs. If a person or an object comes into contact with the print head cartridge, integrated crash sensors set off an immediate emergency stop, halting the machine.

Nyala 2's safety concept was designed with two levels. On the first safety level, the miniTwin2 have to detect objects entering the dangerous area of the machine, slow the print head cartridge from its maximum possible speed of 1.5 m/s down to just 0.3 m/s and warn the operator, says Marc Baumgartner. Of particular note here, is that neither the printing process nor printing quality are affected in slow mode, and therefore no waste is produced either. Interruptions and delays impact on our profitability, and avoiding these things makes the Nyala 2 totally unique, says Petra Fetting from swissQprint's Marketing department. The second safety level is activated when a collision occurs. If a person or an object comes into contact with the print head cartridge, integrated crash sensors set off an immediate emergency stop, halting the machine.

Impressive safety

The miniTwin2's safety concept was well received by swissQprint. It does the job and is very effective, summarizes Marc Baumgartner. Moreover, it gives the user peace of mind and underpins swissQprint's development and systems expertise. It's no surprise then that swissQprint also wants the concept to feature in future models of its machines.

- Product informationen: miniTwin2 safety light curtain

- Product portfolio: Safety light curtains

- Customer information: swissQprint