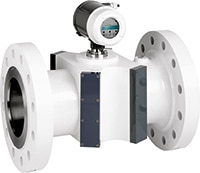

Every day natural gas flows in great quantities through pipelines or into storage facilities. Precise gas quantity measurement is of the utmost importance, as even very small measurement errors could result in substantial economic loss. Challenging ambient measurement conditions like moisture, ice, cold, heat and desert sand place great demands on the instruments in the field. This is why a gas flow meter is needed that is both accurate and reliable. The FLOWSIC600 gas flow meter from SICK achieves both of these goals. It is ideal for both natural gas custody transfer and the highly precise measurement of process gases in the chemical industry.

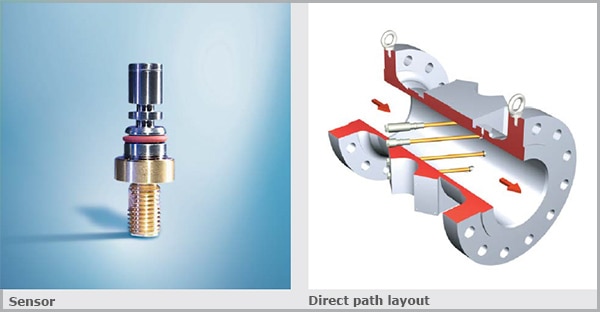

The FLOWSIC600 ultrasonic gas flow meter features a robust meter body incorporating measurement equipment, performs measurement with high noise immunity and long-term stability, and is nearly maintenance-free. The FLOWSIC600 uses ultrasonic measurement and operates without mechanically moving parts making it largely resistant to contamination and wear. The result is maximum measurement reliability even under adverse measurement conditions. For performing ultrasonic gas flow measurement, the transit time difference principle is used. This measurement principle uses ultrasonic transit time to determine the gas flow rate. The direct path layout minimizes the influence of turbulence, contamination, moisture, and background noise. Two ultrasonic sensors are installed opposite each other at a specific angle to the gas flow and operate alternately as a transmitter and receiver.

SICK ultrasonic sensors combine high performance with low power consumption. Due to low power consumption, it is possible to use a stand-alone power supply, such as a solar module.

SICK ultrasonic sensors combine high performance with low power consumption. Due to low power consumption, it is possible to use a stand-alone power supply, such as a solar module.

Automatic Self-Diagnostics

The FLOWSIC600 is equipped with a warning signal that informs the user of a malfunction before the measured value is affected. To do this, current diagnostic indicators are compared to indicators that were learned by the device under normal measurement conditions. The results of the self-diagnostics are permanently logged by an internal electronic data log to allow a retroactive check of the measurement process. Important measured variables such as gas flow and gas velocity (VOG) or diagnostic parameters such as signal-to-noise ratio (SNR) or speed of sound (SOS) can be read directly.

Natural gas pipeline using FLOWSIC600

Natural gas pipeline using FLOWSIC600

Operating Software

MEPAFLOW600 CBM operating software allows efficient and effective meter and data anagement and provides extensive diagnostics options. The software provides simple, user-friendly access to FLOWSIC600 data. MEPAFLOW600 CBM provides permanent online and offline access to the FLOWSIC600. In addition to easy-to-understand visualization, the software supports the user with logs and assistance functions when operating the gas flow meter.

Excellent System Integration

The FLOWSIC600 is available for nominal pipe sizes from DN80 to DN1200 for custody transfer applications, and as small as DN50 for process applications. Easy connection to flow computers allows straightforward integration into any measurement station. SICK also provides inlet and outlet sections, flow computers, and pressure and temperature transmitters.

- Product information: FLOWSIC600 ultrasonic gas flow meter

- Product portfolio: Gas flow measuring devices