Bats and dolphins do it: They orient themselves quickly and reliably using ultrasonics. This versatile technology has been established in industry for many years: It is used for object detection, position determination, and distance measurement. And ultrasonic sensors also show their worth in a variety of tasks in mobile automation.

In contrast to sensors with other physical operating principles, ultrasonic sensors are able to detect objects regardless of their color, surface, and ambient conditions. That is a decisive advantage for the use of commercial vehicles or mobile agricultural machines. For instance, the color of a recycling bin which is automatically picked up and emptied by a collection vehicle is as unimportant for detection as is the restless surface of a corn field or the foliage of a fruit tree. Sun and rain also hardly affect the reliability of ultrasonic sensors: Their housing with high enclosure ratings withstand dust, fog, and rain. The influence of different temperatures on hot or cold days is automatically balanced out by the integrated temperature compensation.

Complying with special requirements and standards

The SICK product range of ultrasonic sensors with different housing variants, operating ranges, and interfaces provides solutions for a very wide variety of tasks in mobile automation. These include agricultural and forestry machines, construction and mining machines, as well as special and municipal vehicles. SICK designs all sensors relevant for mobile automation in such a way that they can withstand the high requirements on impermeability, chemical resistance, temperature influences as well as shock and vibration resistance in their typical rough operational environments.

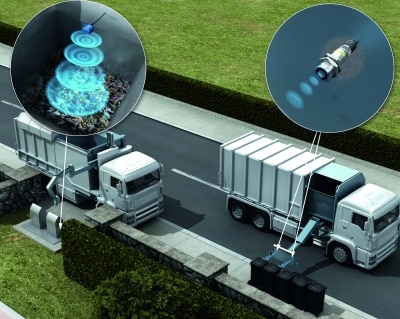

Added value for recyclable material collection vehicles

The use of ultrasonic sensors considerably increases efficiency when collecting recyclable material. For example, the compact UM18-2 in a cylindrical metal housing is used for positioning the automated container gripper arms of the collection vehicle to the fixing points of the recyclable material containers with millimeter accuracy. It is also possible to control the speed of the gripper arms during the approach using the IO-Link or analog output of the sensor. A UM12, which needs even less space, checks whether the position of the collecting container is correct before the recyclable materials are poured in, thereby ensuring a smooth emptying process. Depending on the vehicle, ultrasonic sensors of this product family are also used to report the allocation of an uptake and tilting mechanism and to monitor the temporarily empty area under the container during emptying.

In order to optimize the trips to underfloor containers, it is helpful to inform the driver when the containers are sufficiently full and should be approached. The contamination- resistant UC30 mounted in the underfloor container detects the critical filling level of the container and then triggers an emptying request or delivers the relevant information for optimal trip planning. Every time a recyclable material container is emptied, the level in the vehicle container rises. A UC30 ultrasonic sensor in the compact cubic housing mounted inside continuously measures the increasing level and detects when the critical filling state has been reached. The driver then receives the information that emptying at the disposal site will soon be necessary.

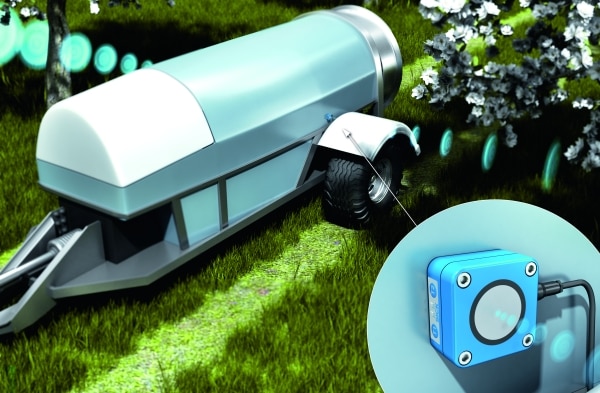

More efficiency in agriculture

Ultrasonic sensors also offer countless fields of application in mobile agricultural machines such as harvesting vehicles. For example, the UC30 is well-suited for level monitoring in the collecting containers on harvesting vehicles due to its large operating range and compact installation dimensions. The UC30 solves another task with spraying devices for fruit growing.

In this application, the sensor detects different tree spacings in groves. The sensor stops the spraying process as soon as the vehicle passes a gap in the trees or when the line of trees has come to an end. Automated detection of trees for controlling the sprayer makes things easier for the driver, and the output of fertilizer or plant protection products is minimized in an efficient way. The lowest possible consumption of spray is also an important goal when applying ultrasonic sensors for the fully-automatic guidance of crop-spraying rod constructions used for cultivating grains and field crops. Depending on the type of construction, up to four UM30 devices are installed. The ultrasonic sensors monitor the working height of the two side sprayer booms and, if needed, adjust it to the plant height of different crops. That is how they ensure as little fertilizer and plant protection products as possible are used. At the same time, the sensors prevent the rod construction from damaging the crop and colliding with areas of uneven ground or other possible obstacles on the field.

Smart automation solutions suited for daily use are created by the integration of ultrasonic sensors in special and municipal vehicles, in construction and mining machines as well as in mobile agricultural and forestry machines. They improve productivity while at the same time lowering operation and material costs. And if the ultrasonic technology is not an optimal fit for the task, the extensive sensor portfolio from SICK offers a wide range of efficient solution alternatives for mobile automation.

- Product informationen: UM18-2, UM12, UC30

- Product portfolio: Ultrasonic sensors