Drivers fit summer or winter tires to their vehicles as appropriate for the time of year. They expect suitable and safe tires that will exhibit ideal rolling, braking, and endurance characteristics at all speeds and temperatures. Tires for trucks and aircraft must also meet these requirements, as must those for many types of construction vehicles, heavy-duty vehicles, and industrial vehicles. This is why the product portfolios of tire manufacturers are so wide and varied. As a consequence, they manage and work with a whole range of very different materials on a daily basis. So, given this mix of materials, how can maximum efficiency be achieved in the material flow in tire production and is it possible to combine this with an assurance of traceability without identification procedures and processes becoming overbearing and unwieldy? SICK offers identification solutions designed specifically for the tire industry which can be relied upon to keep the complex tire manufacturing process running smoothly.

Raw materials including rubber, textiles, and steel (for reinforcing support) are used in the production of tires, along with various chemicals and fillers. The composition of the individual components varies depending on the type and size of the tire being produced. Accordingly, the recipe for a summer tire for a passenger car is not the same as the one used for a winter tire. Similarly, as tires are categorized by speed, their composition will also vary depending on the speed class to which they are assigned. Numerous production stages involving a variety of machines are necessary in order to manufacture tires from this large number of materials. So that each production stage can be completed, it must be ensured that the correct material or the correct component is available at each machine in the required processing state. If the material and the tires produced can be reliably identified and traced at each and every stage of the production cycle, the tire manufacturing process is sure to go in the right direction.

After all, end-to-end identification processes for materials and products combined with seamless documentation of all stages in the process are the key to high process quality. Established identification solutions such as hand-held scanners, bar code scanners, image-based code readers, and RFID read/write devices can be used in such applications. Identification solutions by SICK can be relied upon to identify tires and the materials used in tire manufacturing and guarantee seamless traceability. They also contribute to making just-in-time delivery of the correct tires a reality. All of SICK's identification solutions feature uniform connectivity, an identical user interface, and a uniform accessory concept. What's more, the devices are compatible and interchangeable. This is indicated by SICK's 4Dpro label. 4Dpro reduces the time and effort involved in integration and the technology can be customized.

Identification of materials and tire components

Individual tire components such as treads, inner linings, and inlays are manufactured in pre-production. Each tire component goes through specific production stages. Treads are shaped and cut from raw rubber in an extruder, for example. Inner linings are produced from textile fabric and raw rubber in a calendering machine before being cut to size and spliced in a second machine. The materials required for the production of the tire components are readily available at the corresponding machines. The totes the materials are made available in vary depending on material and machine: Natural rubber and raw rubber are transported inside cages and on pallets; countless rolls of materials inside cassettes are used for textiles and calendered materials. Narrow material treads are wound up and transported on bobbins; shelf trolleys are available for tire treads.

Before materials are fed into a machine for processing, they must be uniquely identified. The identification process must be repeated once the materials have been processed into tire components. In the past, manual identification based on hard copy lists and bar codes which encrypted the part numbers was standard practice. Bar code labels are affixed to the material carriers. At each machine, the bar codes are decoded with mobile hand-held scanners from the IDM16x product family by SICK.

These very rugged scanners are available as hard-wired variants or wireless Bluetooth or WLAN devices. Yet this method of identification brings with it a number of challenges: The bar code label must be resistant in order to remain legible in the face of the harsh ambient conditions that are typically encountered in tire building. As well as taking up machine operators' time, manual data capture also represents a potential error source. Machine operators are constantly having to pull together many different materials and tire components quickly and make them available at the corresponding machines at the right time. Automated identification with passive RFID technology offers an alternative approach. Each of the various material carriers features an RFID tag which is identified by an RFID read/write device. Information about the last or next stage in the process can be written to the tag at the output of each machine. The MES (Manufacturing Execution System) supports combined centralized and remote materials management, so that process information can also be stored remotely on the product. Both HF and UHF technology can be used in this context. All standard passive tags are now available for both technologies in both hard and paper formats or in the special on-metal design. Tags that are resistant to temperature and solvents are also available.

All tags are rugged and durable. In recent times, there has been an increasing trend toward the use of UHF technology, which has a number of advantages over HF technology. It supports larger sensing ranges, for example, and can, therefore, provide solutions for new applications. It is flexible enough to be relied upon to identify tags even if they are located on a variety of materials. Bulk reading is supported for multiple tags, saving machine operators secondary processing time. The UHF solution can be enhanced with the addition of direction-detecting.

RFID read/write devices installed in RFID systems with standard sensing ranges up to 2.5 m. These devices support material traceability across a plant - including in bulk - thereby providing a detailed overview of the current position of the various materials. This ensures that time spent searching is a thing of the past. Various RFID read/write devices from SICK's RFU62x product family can be used for the purpose of material identification in the different machines. The RFU62x is equipped with all industry standard interfaces and has a long reading distance. With the Power over Ethernet variant of the RFU62x, connection is possible with just one connecting cable. The identification status is displayed by easily visible LEDs on the corners of the RFU62x.

Tire identification for tire building, vulcanization, and quality control

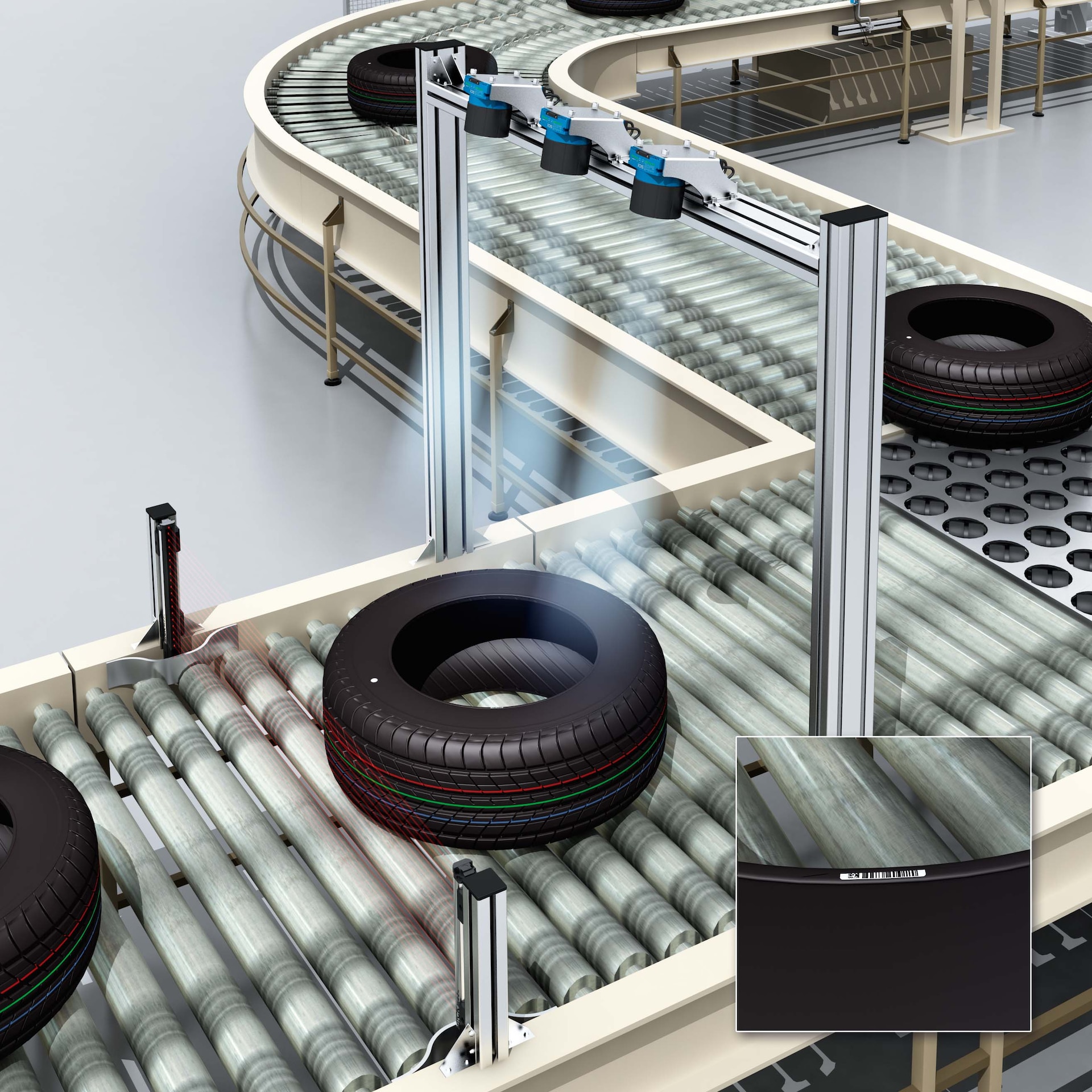

All of the tire components are brought together in the tire building machine, where the raw tires are produced. During its production and until shipping, a tire goes through additional process stages and quality checks. So that all of the stages in the tire building process can be documented and traced, a tire must be uniquely identified at every station.

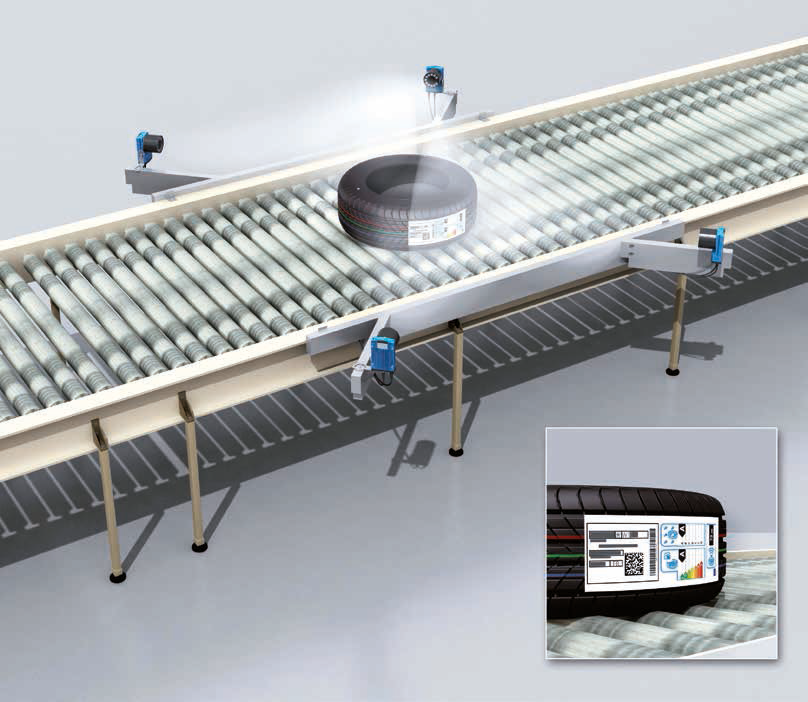

For the purpose of identification downstream in the production process, a bar code label is affixed to the raw tires in the tire building machine either manually or automatically. The tire ID number is encrypted on the label as a bar code. SICK's CLV61x bar code scanner checks the bar code in order to uniquely assign the tire to the ID number. The CLV61x is characterized by its reliable reading performance and compact construction in an industrial design, and delivers an ideal cost-benefit ratio. It also features all of the integration interfaces that are standard in the industry and makes connecting to control systems easy. The Tire Lector Array tire code reading system is used in conveyor technology to identify raw and finished tires regardless of their size. The modular system consists of high-resolution Lector65x image-based code readers and can be individually adjusted to the width of the conveyor. The Lector65x can be relied upon to identify and decode all standard 1D and 2D codes, even if they are of poor quality. The code reader is also available as a matrix camera with dynamic focus which is capable of producing high-resolution uniform images even if the tires are of different heights (as is the case with truck tires, for example). The Tire Lector Array code reading systems can be relied upon to identify bar codes on tires absolutely regardless of how the tires are positioned and aligned on the conveyor.

The sophisticated design of the Tire Lector Array facilitates individual pre-assembly as well as easy installation and maintenance. The system is capable of a throughput of up to several thousand tires per shift and delivers maximum reliability in tire identification. What's more, it is compatible for use in all standard applications in conveyor technology. It can read from above and below, for example, or read tires transported on hooks. As the Tire Lector Array code reading system is able to decode content so quickly, very narrow band gaps can be achieved, in particular for reading from below. The protective cover can be replaced inexpensively, since none of the active elements (the illumination and lenses, for example) have to be changed. As such, the Tire Lector Array delivers high system throughput and is very easy to service and maintain. A raw tire is given its ultimate shape and tread in a curing press, where it is vulcanized. Heat and air pressure are applied from inside to bake together the individual layers for a specific period of time. A raw tire must fit inside the corresponding tire mold, where the external features such as the tread are generated. To ensure that the right tire type is vulcanized in the correct composition, the IDM162 mobile hand-held scanner reads the bar code on the raw tire.

The scanner does much more than just identify the tires. It sends the production data wirelessly to the base station, allowing the entire production history of the blank to be traced. The operator of the IDM162 can read all the information required for the further processing of the tire on the integrated display. Quality control is required to ensure the consistent quality of the tires and thus their reliability and safety. The quality checks that are carried out in the production process include measuring web thickness during the extrusion and calendering process, edge guiding and surface inspection, as well as 3D measurement of the tire shape. After this, the finished tires undergo final tire inspection. As part of this process, the tires are tested for variations in strength, X-rays are taken and checks to identify imbalance are carried out. Before the finished tires reach the inspection stations, they are identified by the Tire Lector Array tire code reading system. Alternatively, a finished tire can be identified and aligned in the spotting station with a camera. The Lector632 image-based code reader reads the bar code label and identifies its position on the tire. This information is used to align the tire correctly for the quality control stations. The depth of field of the Lector632 makes it very flexible, in particular in applications involving tires of different heights. Its wide field of view and high decoding speed enable fast throughput times to be achieved in the station.

Identification of tires and ecolabels in the tire picking station

In accordance with the EU regulation on identifying tires, since November 1, 2012, tire manufacturers have been legally obliged to affix an ecolabel to passenger car tires. The label indicates the fuel efficiency class, the wet grip class, and the class rating of the external rolling noise of a tire, including the corresponding measured value. In addition to the readable text, the label also has a 1D and 2D code. In the picking station, four Lector65x image-based code readers with high depth of field are installed on the conveyor to check the ecolabel on the tire. The position and alignment of the tires on the belt is not important in this context.

Tires that are ready for shipping are stored in shipping racks. Rugged RFID tags on the racks safeguard traceability until the tires reach their ultimate destination. In the robot cell, the SICK RFU62x RFID read/write device by SICK identifies the tag labels containing information about the shipping of the tires. As the RFU62x features numerous integration interfaces, the corresponding data can be sent directly to the warehouse management system. Since the read/write device has a long reading range, the rack does not have to be positioned exactly in front of it.

- More information: 4Dpro from SICK

- Product portfolio: hand-held scanners, bar code scanners, image-based code readers, RFID read/write devices