When commissioning a production order in the production department, e.g. final assembly or engine production in the automotive industry, then various sub-quantities may have to be put together from the total quantity. A pick-to-light commissioning procedure, in which a signal lamp is located on each storage bay, can be implemented in order to display the correct picking tray. The objective therein is to guarantee error-free picking and to reliably guide the machine operator. No problem, with pick-to-light light grids from SICK.

The PLG3 and PLG6 sensors are located in each storage bay and have an integrated Job LED for displaying the picking position and confirming correct access or indicating faulty engagement. Reflective tape on the rear side of every PLG3 and PLG6 sensor also serves as the reflector for the next PLG in the neighboring storage bay. The row also requires another strip of reflective tape for its end.

Product family: smart light grids

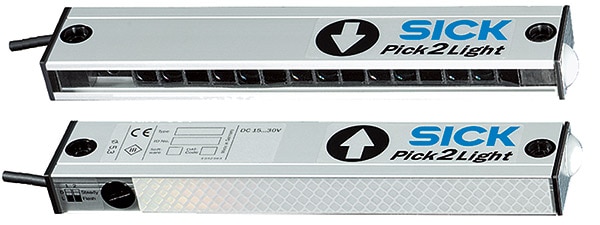

Smart-Pick-to-Light-Lichtgitter SPL

Smart-Pick-to-Light-Lichtgitter SPL

The SICK smart pick-to-light SPL light grid is both the ergonomic and economical solution for access control and stock removal control in storage bays. The SPL is fitted to the side of the picking trays and monitors the engagement area. The SPL is available in two versions: Slim and Flat. The green Job LED indicates the picking tray to the operator and optically confirms correct removal - in the event of erroneous removal, the red LED will light up. SICK offers an extensive portfolio of various pick-to-light solutions, each having different features to match your requirements. For you, these solutions mean: No parts mix-ups, no missing parts, no reworking, regardless of which system you opt for.

Benefits of the PLG3:

The design of PLG3, with its single-sided reflector strip, saves space in the container, reduces damage, and reduces installation costs. Thanks to an integrated polarizing filter, the PLG3 is highly insensitive to glare.  It has 30 mm beam separation and is available with various monitoring heights. The integrated green Job LED reduces order-picker search time.

It has 30 mm beam separation and is available with various monitoring heights. The integrated green Job LED reduces order-picker search time.

Benefits of the PLG6:

With a beam separation of 60 mm, the PLG6 is particularly suitable for small monitoring heights. The PLG6 design, with its single-sided reflector strip, saves space in the container and reduces damage.  At the front of the housing, it has an integrated red Job LED that is visible to the order picker at a 180° angle and can draw his/her attention to both faulty engagement and the correct picking position.

At the front of the housing, it has an integrated red Job LED that is visible to the order picker at a 180° angle and can draw his/her attention to both faulty engagement and the correct picking position.

Benefits of the SPL:

The SPL has green Job LEDs along the entire sensor, offering reliable indication of removal for the order picker. Optical synchronization, the automatic teach-in button, and alignment aid enable quick installation and cost-effective connection. Furthermore, the SPL can be installed in two ways: Slim and Flat. It can thus offer both ergonomic and flexible adjustment in the installation.

The SPL has green Job LEDs along the entire sensor, offering reliable indication of removal for the order picker. Optical synchronization, the automatic teach-in button, and alignment aid enable quick installation and cost-effective connection. Furthermore, the SPL can be installed in two ways: Slim and Flat. It can thus offer both ergonomic and flexible adjustment in the installation.

- Product information: PLG3 standard automation light grid, PLG6 standard automation light grid, SPL smart light grid

- Product portfolio: Standard automation light grids , smart Light Grids