Orfer Oy is a leading supplier of packaging and automation systems for the food industry and is located in Finland. A 3D vision solution jointly implemented with SICK ensures that all bread rolls are correctly detected and properly packaged at a packaging robot.

Keeping bread rolls properly apart: 3D vision solution for the food industry

SICK is a long-standing cooperation partner of Orfer Oy. The two partners are continuously finding solutions for the development of innovative systems for the food industry.

Automation solutions for the food industry

“Orfer is a family business that was found in 1970 and is a leading supplier of automation solutions for secondary packaging and palletization in the food industry,” says Mikko Arponen, Head of Marketing at Orfer, and adds: “The first systems we developed were for the treatment of sawn timber. Having mastered the handling of piece goods, our focus also shifted towards the food industry.”

Orfer employs 100 specialists in automation systems and production. Its headquarters, R&D department, and its production facilities are located in Orimattila in Finland. Orfer also has branch offices in the Finnish cities of Keuruu and Ylöjärvi as well as a subsidiary in Canada. To date, the company has delivered almost 1,000 automation solutions in more than 20 countries.

“Our systems, which are tailored to the requirements of the customer, are flexible and efficient,” says Arponen and adds: “Automation saves packaging materials, and the optimal filling of transport units saves space and makes transport more efficient. All of this enables companies to operate in a more cost-effective and environmentally friendly manner.”

Bread rolls for export in thermoformed packaging

The Finnish bread baking company Pekan Leipä bakes organic rye bread. These are divided at the end of production and the two divided parts are packaged into each packaging unit before being exported to Germany, among other places.

On the old packaging line, this processing required a lot of manual work. More than 10,000 bread rolls per hour come out of the ovens and need to be packaged. This work is monotonous, and it is difficult to find employees for this kind of task – to say nothing of the cost.

Inspection and placement of the bread pieces

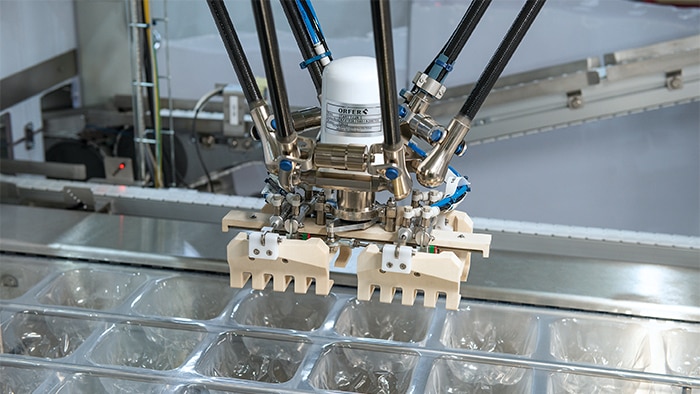

In this robot cell, three delta robots operate with a high pickup speed. This is required when two conveyor belts transport several bread rolls per second into the cell. The robots take the rolls from the belt and lay them pairwise into the thermoformed trays.

The correct pickup and placement of the rolls requires that the upper and lower halves of the rolls are lying exactly on top of each other when they arrive at the robot cell. For this purpose, the conveyor belt is equipped with an inspection station at the heart of which is a TriSpector1000 3D vision sensor.

The TriSpector1000 is a configurable standalone sensor for the three-dimensional inspection of moving objects. It generates a line-by-line height profile of the object and produces a complete view based on the movement of the object. The movement information can be obtained by measuring the speed of the object or, as in this case, using an incremental encoder attached to the conveyor belt.

At the inspection station, the TriSpector1000 generates data on the height, length, and area of each piece of bread. If only one half of the roll has been transported on the belt, its height would be too small and therefore sorted out. If, on the other hand, the two halves of the roll overlap, i.e are not lying exactly on top of each other, the result would be a too long object and would therefore be rejected. The inspection station has a pusher that pushes the rejected objects off the belt.

3D vision camera as the right solution

For Harri Vartiainen, who develops automation solutions for Orfer, the TriSpector1000 – along with numerous other SICK sensors that are used in the system – was also an obvious choice. He says: “This 3D vision camera was a good and cost-effective solution for implementing this system. The colors of the products were not an issue in this application, the 3D camera has its own illumination, and it was easy to install. A 2D camera might perhaps have been a more economical alternative, however the TriSpector1000 is very reasonably priced compared to competitor products. And the application possibilities are very, very diverse.”