The containers filled with falafel or hummus specialities whiz by at lightning speed. But how much is actually currently being produced and how much is still needed to satisfy all the incoming orders? The specialists at “NENI am Tisch” in Austria want to know this precisely. The sensor technology from SICK provides the answer.

Hummus, falafel and more: delicacies on the conveyor at NENI

Those in our part of the world who love hummus or falafel are certain to know “NENI”, alias Haya Molcho, as well. She opened her first NENI restaurant in 2009 at the Vienna Naschmarkt. NENI is an acronym formed from the first letters of Haya Molcho's four sons: Nuriel, Elior, Nadiv and Ilan. The result is a success story. Within just a few years the family company grew to 13 restaurants – the Vienna Naschmarkt was followed by Prater and NENI am Wasser, also in Vienna, as well as further restaurants in Berlin, Hamburg, Munich, Cologne, Copenhagen, two in Zurich as well as Amsterdam, Paris and Majorca. NENI am Tisch can also be found in around 1,600 stores of the Spar supermarket, and the company has a Europe-wide cooperation with the “25 Hours” hotel chain.

Everything fresh – in a new manufacturing facility

With this rapid growth, production quickly hit its limits because NENI doesn’t produce to stock. Everything is fresh and quickly shipped. A new location was required with more space and new machines. A new home for the manufacturing facility and NENI's headquarters was therefore built in Gumpoldskirchen in Lower Austria. Since August 2021 they have been producing delicious oriental salads, spreads and lots more here. With a total floor space of 3,176 m2, it provides a perfect home base to also expand the range of tasty creations in future.

Hummus, falafel and more – on two fully automatic filling systems

25 different products – such as baba ganoush, hummus and falafel – are continuously prepared fresh in Gumpoldskirchen. “We produce around 150,000 kilograms of delicacies per month,” says Bernhard Balzer, Manufacturing Operations Manager at NENI. Half of it is hummus in different varieties – from beetroot hummus to curry hummus. These are manufactured using, among other things, two fully automatic filling machines. “In the hygienic area, the products are dispensed into containers using bulk goods filling machines or filling machines for paste-like contents. The containers are then sealed or covered with a lid and travel through X-ray detectors to the scale inspection area where each container is weighed individually prior to final packaging,” explains Balzer.

Container by container: precise control of production

Every manufacturing line is, of course, equipped with a piece counter, cycle counter, and throughput measuring system, but due to the downstream sorting operations the actual packaged and ready to ship products no longer correspond, however, to the total quantity of product at the machines. Bernhard Balzer: “We take manufacturing control very seriously. Incorrect filling, for example, is reliably detected. Product is sorted out at every control point. We nevertheless want to know what actually comes out at the end, i.e. what the effective number of containers per minute and line is. Only then can we precisely control the production and fulfill all our orders without having to store products for longer periods of time. This is an important factor for freshness, which our guests and customers appreciate so much.“

Accurate evaluations desired

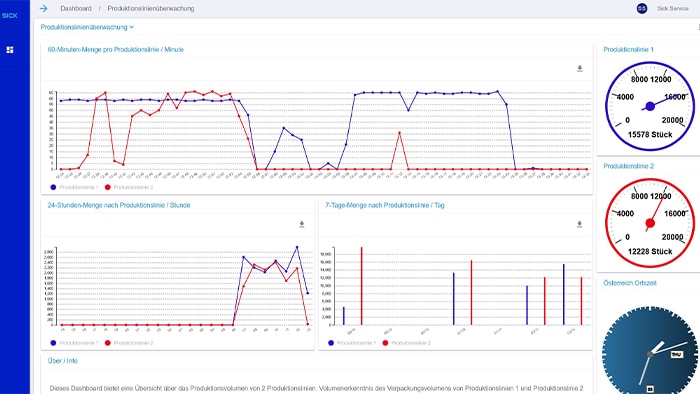

The previously available evaluation capabilities with regard to the final quantity were unsatisfactory for Bernhard Balzer and his team. “We wanted to know, among other things, what the average hourly output actually looks like at different utilization rates,” the operations manager explains. We were therefore not only looking for a sensor solution to count the containers, but also the ability to display the data delivered by the sensors on a dashboard. “According to the manufacturer of the filling systems, the maximum output that can be achieved is 65 to 70 containers per minute. This varies, however, due to the different filling processes. When a very viscous mass is dispensed, for example, the work process slows down. Putting on the lids also reduces the speed. You could see on the screen of the system how many containers per minute are currently being produced and the projected number of containers per hour. With changing products and work speeds however, these projections were no longer correct. It was also not possible to trace product or display downtimes,” says Balzer.

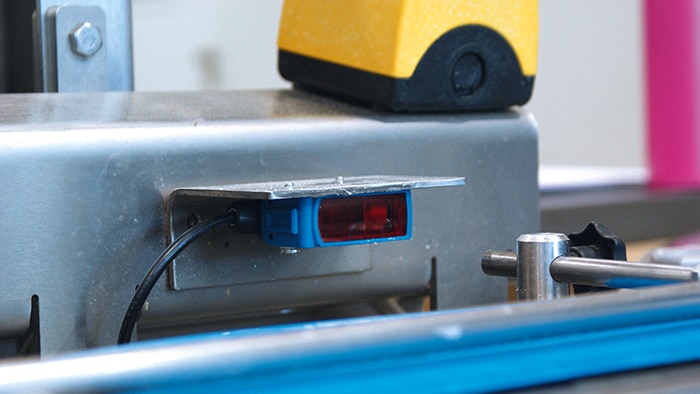

Sensors to determine the container count and visualization on a dashboard

An important part of the solution at NENI was a W16 optical sensor from the sensor specialist SICK that determines the container count as a result of the interruption of the photoelectric sensor – perfect for object detection, even at high speeds. A further requirement was a clear visualization on a screen, tablet or cell phone to allow remote access. To achieve this, the sensor was connected to a SIG200 sensor integration gateway and integrated into the company network in coordination with the IT department at NENI. This enables the collected data to be easily accessed and displayed via a conventional web browser. Some customizations were also done in cooperation with NENI and SICK. For example, the actual quantity produced in the last hour can now also be displayed. Bernhard Balzer: “Whether it be hourly or daily production or live information for the previous minute – I only need to log into the server, then I can view fully up-to-date information from anywhere in the world.”

Precise quantity produced to-order

Thanks to this sensor solution, NENI can now produce precise quantities – exactly as ordered. Bernhard Balzer: “This means, for example: We receive orders at 11:00 am on a Monday and that same afternoon we produce everything fresh into the night. On Tuesday we are already filling the containers, and by 5:00 pm at the latest the trucks with the already expected goods leave Gumpoldskirchen. A very small time window that needs to be optimally utilized because production of the next orders will already start on the next day. This can only work if we know our production very well and have everything under control – the sensor solution from SICK was essential for this.”