Clima e gestão da proteção ambiental na SICK

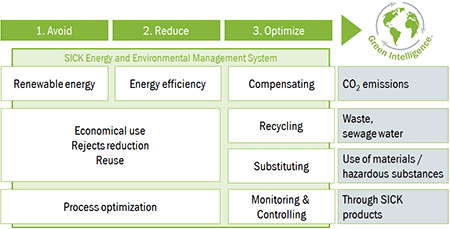

As atividades para a proteção do meio ambiente são orientadas para a estratégia de proteção do clima e do meio ambiente. A máxima aqui é: a SICK quer acabar completamente ou minimizar continuamente os impactos ambientais, (que podem ser) causados por produtos e processos, no âmbito dos recursos disponibilizados pela empresa.

- EVITAR o que pode ser evitado.

- REDUZIR o que não é evitado.

- OTIMIZAR o que não pode ser reduzido.

O foco recai, com isso, sobre os quatro domínios de ação das emissões de CO2, resíduos e águas residuais, utilização de materiais, assim como utilização de produtos SICK nos clientes.

Adhering closely to the tradition of the company founder, Dr. Erwin Sick – who showed a passionate concern for the environment as early as 60 years ago – SICK has therefore made a conscious decision to develop the company in a sustainable way. In order to minimize the negative environmental impact during the production process to the greatest degree possible, SICK follows a three-tiered climate and environmental protection strategy:

- We avoid what we can.

- We reduce, what we cannot avoid.

- We optimize what we cannot reduce.

The basis for SICK's strategy is formed by an environmental and energy management system that has been firmly established within the company for a number of years. SICK publishes an annual environmental statement in accordance with the EMAS standard, which uses core indicators to provide information about all relevant environmental impacts and the environmental objectives derived from them. SICK achieves these environmental objectives by implementing projects in a wide range of divisions within the three tiers that are defined in the climate and environmental protection strategy. The focus here is placed on four areas of activity:

- CO² emissions

- Refuse and waste water

- Material usage and hazardous substances

- Through SICK products

All sites in Germany and the manufacturing subsidiaries in Hungary, the USA and Malaysia are certified according to the ISO 14001 environmental management system. In addition to this, the headquarters in Waldkirch, the site in Reute, and SICK Vertriebs-GmbH in Düsseldorf have an environmental management system in accordance with EMAS (Eco-Management and Audit Scheme) and a certified energy management system according to ISO 50001

A selection of real-life examples

In 2011, a total of 975 m² of photovoltaics were installed and operated by external investors on the SICK roofs at Reute and Waldkirch. SICK has provided a total area of 1375 m². An installed capacity of almost 170 kWp generates approx. 160,000 kWh of power on SICK AG roofs every year.

For quite some time now, companies in many different sectors have been using SICK sensors to streamline their production processes and thereby conserve resources. Even in its own processes, SICK takes care to ensure that the materials and equipment it uses are as environmentally friendly as possible. The gradual switch to water-based painting systems is saving up to 3.5 tons of solvent emissions every year!

Reliable and efficient electronics are at the heart of all SICK sensors. But even this demanding manufacturing process makes use of environmentally friendly methods. Lead-free soldering has been in place at SICK since 2006 and is available for use in new developments.

Kerstin Kohler

Gestão ambiental

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

+49 7681 202 - 5282

kerstin.kohler@sick.de