With SAM inductives, the system does not need high-end PLC or PC-based controllers. The result is a simplified control system which is cheaper now.

1.5.2 Simplifies commissioning & calibration

Lastly, SAM inductive shortens commissioning time and effort. During process commissioning, the engineers need to teach the system when and how to react. When using classic method, the engineers need to measure the system characteristics. Next, they need to write comparison algorithm and lookup table for the controller.

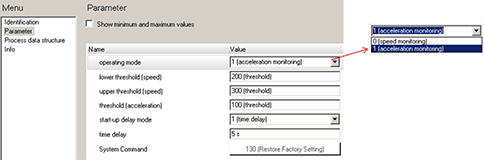

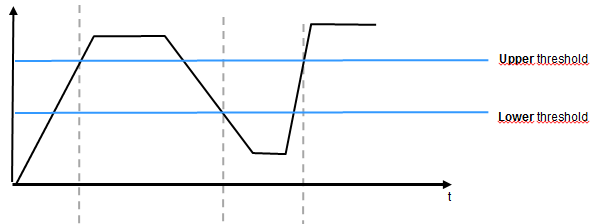

With SAM, commissioning the system is much simpler. The engineers just setup the SAM’s threshold trigger via IO-Link. No physical information is required on shaft speed and acceleration. The SAM will process all data and interrupt the system controller should the actual shaft speed or acceleration falls out of SAM pre-set threshold. This saves a lot of commissioning time and resources.

1.6 Conclusion

The new Speed-Acceleration Monitoring (SAM) inductive sensor is designed to simplify factory automation process. With SAM inductive, the bandwidth consuming task of computing angular speed and acceleration data can be offloaded by system PLC to this sensor. This results in a simpler control system, which drives cost down. In addition, system commission and calibration is also made easier.

SICK is one of the world's leading manufacturers of sensors and sensor solutions for industrial applications. Founded in 1946 by Dr.-Ing. e. h. Erwin Sick, the company is headquartered in the German town of Waldkirch, in the Breisgau region near the city of Freiburg. It is a technology and market leader, maintaining a global presence with more than 50 subsidiaries and equity investments as well as numerous representative offices. In the 2014 fiscal year, SICK had around 7,000 employees worldwide and generated Group revenues of €1,099.8 million.