Up to now, functional safety technology in automation has mostly been implemented separated from fieldbuses and Ethernet networks. But the next microScan3 generation sets new standards: The microScan3 Core – EtherNet/IP™ is the first safety laser scanner on the market to offer CIP Safety™ over EtherNet/IP™ and is compatible with all commonly used EtherNet/IP™ CIP Safety™ controllers. The microScan3 Core – PROFINET enables safe and reliable bus communication using the PROFIsafe protocol. The PROFINET IO bus connection is used to process all signals from the higher-level controller (fail-safe programmable logic controller).

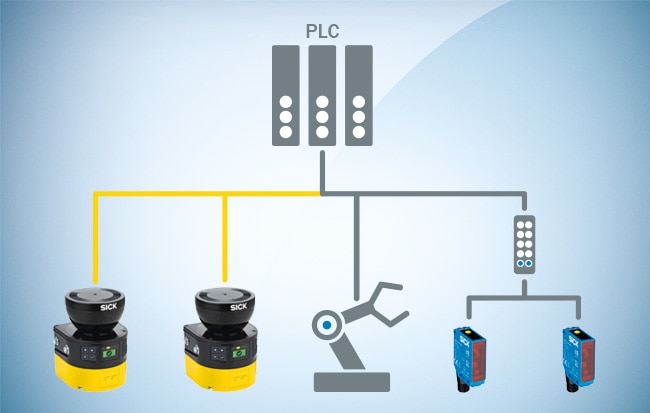

The integration of safety functions into the network makes it possible to share safety signals and non-safe process data over the same network. This opens up new possibilities, e.g., for visualization and for transmitting status information to higher-level ERP and MES data systems. The automotive industry is leading the way in this area. It is there that the first scanner at the time to offer a direct interface to the controller made its debut on a grand scale. After a positive market response, we enlarged the family of SICK safety laser scanners with the microScan3 Core I/O with the innovative scanning technology safeHDDM®. Now, we join an additional pair of family members: the larger, network-compatible devices microScan3 Core – EtherNet/IP™ and microScan3 Core – PROFINET.

Central access options for straightforward diagnostics and maintenance

Both network variants can protect multiple hazardous areas at the same time, and provide up to four simultaneous protective fields that allow several conventional I/O scanners to handle the job. This means that these laser scanners help to reduce purchasing costs while boosting productivity. Integration into existing safe controllers and control cabinets meets current safety standards and is hassle-free. In addition, the new variants save users a great deal of time, since the devices can be configured incredibly quickly and easily over the network. As an added benefit, safety laser scanners are protected against tampering. To achieve this, the sensor transmits a checksum of the safety configuration to the control computer, which allows to detect and trace any unauthorized changes made to the field device.

Because configuration can be performed from a central operating computer, the entire commissioning process is quicker and easier. The same is also true when it comes to operating and maintaining the sensors. Because all data is stored in a central location, anyone accessing it will always receive the single most current version, resulting in guaranteed data integrity.

Diagnostics data available anywhere

The opportunities to use a multitude of data to produce and supply goods in a more efficient and flexible way – while also saving resources and attaining higher quality – ultimately depend on the reliability and robustness of the data that represent the input for the process chain. They therefore also depend on the sensors that detect the real conditions and convert them into digital signals. Even in its most basic version the microScan3 safety laser scanner sets new standards for reliability and robustness thanks to the innovative safeHDDM® scanning technology. With the network variants for direct and safe integration into fieldbuses it is also possible to integrate sensor data into preventative maintenance concepts, among other things. For example, information provided by the sensor about the contamination level on the front screen is automatically reported to the automation system – far enough in advance to prevent potential negative impacts on performance or a safety-related plant shutdown. If problems within the system are encountered despite this feature, any errors that may have occurred can be quickly identified and analyzed from a central location. This means that quick response times are possible – which keeps potential downtime to a minimum. It would be a shame if all those data were not available on a network ...