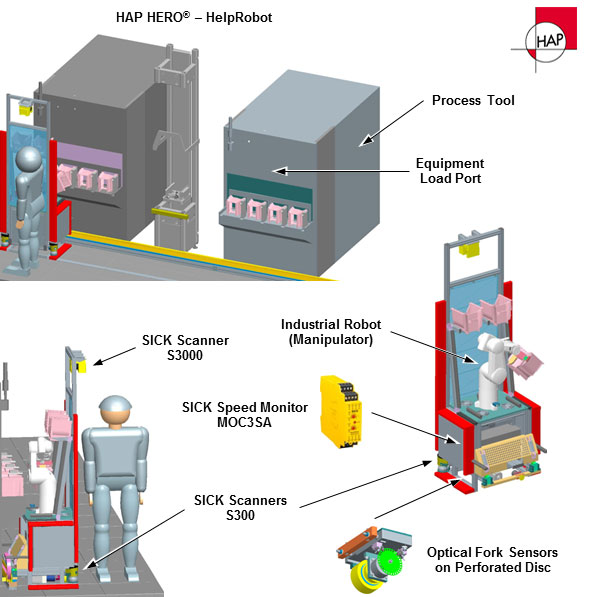

HAPs HelpRobot is a mobile and flexible robotics solution for handling tasks in the semiconductor industry. This robot, from Dresden located HAP GmbH, is being used at Infineon Technologies in Dresden. Depending on whether persons are present in the area around the robot, the HelpRobot is at a standstill or moving at creep speed or at the maximum speed of 400 mm/s, equipped with safe speed monitoring solutions from SICK.

MOC3SA Speed Monitor: the motion control module for safe speed

Developed for safety-capable speed monitoring of drives, the MOC3SA Speed Monitor from SICK meets safety levels PL e in accordance with EN ISO 13849, SIL3 in accordance with IEC 61508, and SIL3CL in accordance with EN 62061. The motion control module allows implementing both safe zero-speed and drive monitoring applications in simple, flexible, and cost-effective ways. Installed on HAPs HelpRobot, the Speed Monitor detects the speed of the robot using two fork sensors that scan a perforated disc mounted directly on the vehicle axle. In terms of safety technology, the Speed Monitor communicates with the safety controller of the HelpRobot and, through this channel, with the drive itself. If the respective maximum admissible speed is exceeded, the Speed Monitor safely switches off the drive by means of the motion controller.

Speed Monitor provides economical safety

At HAP, technical reasons were not the only arguments in favor of SICKs Speed Monitor; so were economical aspects. The module delivers convincing performance due to its easy configurability. With the aid of the free Flexi Soft Designer software, one can lay out and test the safety application in a time-saving way - what is more, a screwdriver suffices to adjust the Speed Monitor. In addition, using the Speed Monitor allows doing without a safe drive, which saves several hundreds of euros per HelpRobot.

The MOC3SA Speed Monitor is the ideal solution to monitor the speed of drives in terms of safety technology. This applies not only to the application featured here but also in general to operational settings that involve machinery and technical facilities.

- Product information: MOC3SA Speed Monitor safety controller, S300 safety laser scanner, S3000 safety laser scanner