Time and space are money. This is why it is of special importance in intralogistics to make best use of the warehouse space available. The STILL GmbH is a producer of forklift trucks and intralogistics systems. For an optimal usage of storage space they offer the semi-automatic storage system "STILLPalletShuttle". In terms of safety technology in fully automatic operation of the storage system STILL uses safety laser scanners from SICK.

The STILLPalletShuttle is a semi-automatic storage and retrieval system comprised of a shuttle and a multi-level storage system with channels. It optimizes the use of storage space and increases both the transfer of pallets and throughput performance. The S300 is the crucial component of the extensive vehicle safety design that STILL worked out jointly with the German Accident Insurance Association for Trade and Distribution of Goods.

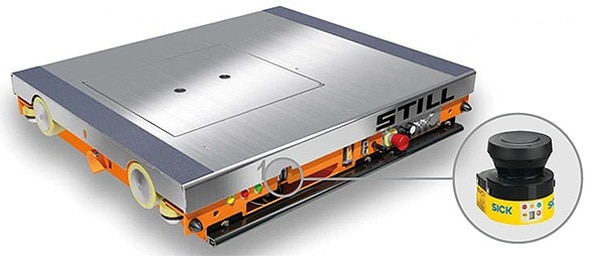

The STILLPalletShuttle is a semi-automatic storage and retrieval system comprised of a shuttle and a multi-level storage system with channels. It optimizes the use of storage space and increases both the transfer of pallets and throughput performance. The S300 is the crucial component of the extensive vehicle safety design that STILL worked out jointly with the German Accident Insurance Association for Trade and Distribution of Goods. STILLPallettShuttle

STILLPallettShuttle

The STILLPalletShuttles achieve a maximum level of availability by means of distinguishing various kinds of obstacles. As soon as the S300 detects a potential obstacle, the shuttle reduces its speed dynamically all the way down to a creep speed of 0.1 m/s. If in the process of continuing travel, the emergency stop bar on the shuttle gently touches an obstacle, it triggers an emergency stop - i.e. doing so only if the obstacle really makes onward travel impossible. This has the great advantage that the shuttle does not trigger an emergency stop every time it encounters something, e.g. packaging film hanging down, instead slowly passing underneath the hanging film, explains Gérard Lacher, Head of the Intralogistics Systems department at STILL. Safety laser scanner S300

Safety laser scanner S300

The safety laser scanner, developed especially for mobile applications also, fulfills the safety-relevant requirements of performance level d in accordance with EN ISO 13849 as well as SIL2 in accordance with IEC 61508 and meets the demands on optoelectronic safety devices in accordance with Type 3 of IEC 61496. In every STILLPalletShuttle, the sensor takes on the monitoring of travel in the semi-automated storage and retrieval process. For the vehicle platforms with a height of only 191 mm, the compact design of the S300 was the deciding factor - even though it was not the only one: The safety laser scanner is also a real energy saver, supporting the energy supply design of the STILLPalletShuttles that is laid out for extended operating times without recharging. The S300 meets the requirements for safety, combined with minimum installation space and flexibility to implement complex safety applications.

- Product information: S300 safety laser scanner S300

- Product portfolio: Safety laser scanners

- Customer information: STILL GmbH