-

Home

-

SICK Sensor Blog

-

Decarbonization: gas analysis and flow measurement for transfer and process applications

-

Home

-

SICK Sensor Blog

-

Decarbonization: gas analysis and flow measurement for transfer and process applications

Decarbonization: gas analysis and flow measurement for transfer and process applications

Oct 16, 2023

The most important approach for reducing CO2 emissions in the oil and gas industry is the separation of carbon dioxide, and its transport via pipelines or ships. In the future, more and more pipelines will be transporting not only gas but also hydrogen. SICK offers a wide range of products for gas analysis and flow measurement.

Welcome to part two of our series on decarbonization where we focus on the oil and gas industry

Decarbonization in the oil and gas industry using CCUS (Carbon Capture Utilization and Storage)

CCUS is currently one of the most effective methods in the area of gas extraction and transport for reducing or even eliminating CO2 emissions. The carbon dioxide from various emission sources can be separated, collected, and transported via pipelines or ships for further processing steps such as storage or use.

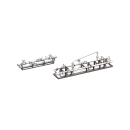

The direct air capture method can also be used to remove carbon dioxide from the air. Gas flow measurements are required at every transfer point to check or invoice the quantity of captured CO2, the stored volume, or the transfer to another company for use. Accurate gas metering using the FLOWSKID flow metering system allows for precise accounting to companies or calculation of the CO2 taxes and credits.

Flow metering systems

Reliable turnkey solution for fiscal metering

FLOWSKID

Regardless of the destination of the separated CO2 (storage or use), it is important to measure and check the quality of the gas and any contaminants it might contain. Contaminants can have a negative impact on subsequent steps and processes in the distribution of the CO2. SICK offers various technologies for this, from extractive measurement solutions through to in-situ measurements. The GMS800 extractive gas analyzers, and MCS200HW or MCS300P HW CEMS solutions measure the quality and purity of the CO2. The GM35 in-situ gas analyzer also measures the CO2 concentration. The FLOWSIC600-XT gas flow meter determines the exact gas flow rate.

SICK also offers various digital solutions as well as data processing solutions such as the FLOWgate configuration software, and i-diagnostics™, which provides data on the device status. The Monitoring Box is used to analytically process status and application data.

Reliable measurement of natural gas/hydrogen mixtures using SICK gas flow meters

The generation and storage of renewable energy with the help of clean and energy efficient technologies are an important building block for future energy supply. The conversion of electricity from wind power plants or other environmentally friendly energy sources into hydrogen – e.g. via electrolysis – will play a significant role in this. Only in this way, the energy be stored efficiently or transported over longer distances.

More and more customers also want to feed the hydrogen into the gas network to reduce their CO2 emissions and then use the gas mixture at a later time, e.g. in gas turbines. The technology is expected to make significant inroads in the coming years. More than 20% hydrogen is expected to be fed into the gas networks very soon. This introduction of hydrogen poses great challenges and issues for the industry – for example how to reliably measure the flow and quality of the hydrogen.

The gas flow meters from SICK already offer this today because, for example, the FLOWSIC600-XT measures the concentration of H2 in natural gas.

Read the other parts of our series on decarbonization

Please wait a moment...

Your request is being processed and may take a few seconds.