A sensory check can mean two things in the context of ice cream. Namely, the sensual experience of the chocolate coating cracking as you bite into it, followed by the explosion of flavors. Or it can refer to the quality check carried out by sensors in the manufacturing and packaging process. On the type HK 4 horizontal cartoner of Dienst Verpackungstechnik GmbH, the latter is undertaken by equipment including image-based code readers and vision sensors from SICK. Ice cream on a stick is a matter of taste. Whether you love caramel, chocolate, strawberry, raspberry, or almond, an assorted selection, or maybe even one of each flavor - Unilever satisfies the taste of every ice- cream lover. The company states that it sold 1 billion Magnums on sticks in 2014. One part went onto the market as single portions, the other as multipacks. The correct batch assignment according to size, flavor, and quantity plays a crucial role in secondary packaging in multipacks. Ice-cream lovers want to be certain that the packaging contains the type of ice cream they chose, that it was processed quickly (cold chain), and that the marked use-by date provides reliable information about the freshness of the product. The ice-cream manufacturer and plant operator must also be able to ensure that the packaging machine correctly packs and seals different cartons with various assortments. The changing designs of folding boxes thereby present a further challenge.

Format variety on a single machine

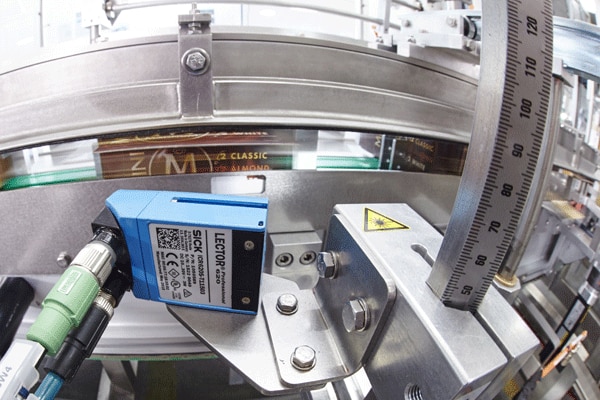

The HK 4 horizontal cartoner is a top model from Dienst and automates the packaging process of pre-glued folding boxes, thus meeting the highest requirements in terms of format variety, short set-up times, ergonomics, and reliable machine availability - all while handling products gently. The type HK 4 horizontal cartoner has a modular structure. The 6-inch variant is a small and compact machine, which can process up to 300 folding boxes per Minute.  The ice cream does not need to be kept in a freezer- while it is being packaged into folding boxes. Downstream in the production line, the HK 4 deals with the incoming single packs, for example the ones for the six-packs of the Magnum Mini White, Almond, and Classic. A Lector620 Professional image-based code reader from SICK reads the QR code on the folding box. If this information matches the production plan data, the incoming ice-cream assortment is inserted into the folding box by a pusher. Firstly, we spread the tabs on the box apart, put the products inside, and then we seal the tabs. No later than when the first box reaches the QR code reader, I can check if the data on the box matches the production data, says Roland Kaluza, Construction Manager at Dienst Verpackungstechnik GmbH, explaining the process. As soon as the box is put in an upright position, the lower tab is pushed upward and, after glue has been applied, the covering tab is pressed down. The box is closed.

The ice cream does not need to be kept in a freezer- while it is being packaged into folding boxes. Downstream in the production line, the HK 4 deals with the incoming single packs, for example the ones for the six-packs of the Magnum Mini White, Almond, and Classic. A Lector620 Professional image-based code reader from SICK reads the QR code on the folding box. If this information matches the production plan data, the incoming ice-cream assortment is inserted into the folding box by a pusher. Firstly, we spread the tabs on the box apart, put the products inside, and then we seal the tabs. No later than when the first box reaches the QR code reader, I can check if the data on the box matches the production data, says Roland Kaluza, Construction Manager at Dienst Verpackungstechnik GmbH, explaining the process. As soon as the box is put in an upright position, the lower tab is pushed upward and, after glue has been applied, the covering tab is pressed down. The box is closed.  If a QR code has been read as incorrect, the machine records this error and automatically separates the folding box concerned from the packaging process without interrupting it. If three boxes have been read as incorrect using the QR code, the machine stops as the QR data does not match the production control data, thus avoiding packaging errors. In principle, the entire value chain can be monitored based on QR codes, explains Roland Kaluza. Food production and packaging are subject to particularly strict quality rules. Ice cream is one of the sensitive food items. Up to 180 folding Magnum boxes are filled per minute on the HK 4. There are currently seven different box sizes for different packaging patterns. The single packs are either arranged in one or two rows, or in two blocks of three, four, or five rows. The folding boxes are only given their use-by date through laser printing at the end of the packaging process. The Inspector vision sensor from SICK verifies that the date is imprinted. The multipack is complete.

If a QR code has been read as incorrect, the machine records this error and automatically separates the folding box concerned from the packaging process without interrupting it. If three boxes have been read as incorrect using the QR code, the machine stops as the QR data does not match the production control data, thus avoiding packaging errors. In principle, the entire value chain can be monitored based on QR codes, explains Roland Kaluza. Food production and packaging are subject to particularly strict quality rules. Ice cream is one of the sensitive food items. Up to 180 folding Magnum boxes are filled per minute on the HK 4. There are currently seven different box sizes for different packaging patterns. The single packs are either arranged in one or two rows, or in two blocks of three, four, or five rows. The folding boxes are only given their use-by date through laser printing at the end of the packaging process. The Inspector vision sensor from SICK verifies that the date is imprinted. The multipack is complete.

Lector620 Professional image-based code reader

The sensors of the Lector62x product family are compact, image-based code readers, specifically tailored to industrial requirements. They identify the most commonly used code types on mobile or stationary items with exceptional reliability - even poor quality codes. The highly compact design ensures flexible integration even where space is at a premium. Lector620 Professional code readers are universal and economical.

The sensors of the Lector62x product family are compact, image-based code readers, specifically tailored to industrial requirements. They identify the most commonly used code types on mobile or stationary items with exceptional reliability - even poor quality codes. The highly compact design ensures flexible integration even where space is at a premium. Lector620 Professional code readers are universal and economical.

Integration

The compact and rugged metal housing with enclosure rating IP 65 - optionally IP 67 - is up to two thirds smaller than in most other industrial 2D code readers. Housing slots and sliding nuts with variable distances between the holes, as well the M12 swivel connector, ensure safe and quick mounting at any time. There are also diverse options for integrating code readers into their respective IT environment easily and openly. Ethernet TCP/IP, FTP, EtherNet/IP™, PROFINET, CANopen, serial interface, digital I/Os - with the Lector62x product family, all the relevant data interfaces are integrated in the respective device. A USB interface is also integrated in all devices, which enables extensive service and diagnostics functions.

Inspector: intelligent image processing solution in a convenient sensor package

The Inspector vision sensor for image processing applications represents an intelligent solution in a single device, no matter the task: quality and completeness verification, part position detection, or measuring applications. The rugged IP 67 metal housing is designed for industrial use and, thanks to its intelligent image processing, the Inspector is perfect for applications involving high speeds. The variable mounting options are designed to adapt easily to the optical requirements of the customers given application. This ensures an excellent inspection, even of objects that are difficult to detect, such as strongly reflective parts or multi-colored labels. The Inspector product family offers extensive support in controlling, monitoring, and data collection thanks to numerous interfaces. A multitude of new ice-cream varieties are launched on the market annually. This increase also leads to a greater diversity of folding box designs. For instance, now there is the new Magnum box with rounded edges and its exclusive eye-catching design, for as everyone knows you first eat with your eyes.The HK 4 horizontal cartoner ensures error-free packaging of different ice-cream batches and assortments in diverse folding box designs. Nothing stands in the way now of the sensory check at the end of the value chain - that is to say, when the ice-cream lover gets to taste the ice cream. There is no accounting for taste as they say. Unless its the wrong one...

The Inspector vision sensor for image processing applications represents an intelligent solution in a single device, no matter the task: quality and completeness verification, part position detection, or measuring applications. The rugged IP 67 metal housing is designed for industrial use and, thanks to its intelligent image processing, the Inspector is perfect for applications involving high speeds. The variable mounting options are designed to adapt easily to the optical requirements of the customers given application. This ensures an excellent inspection, even of objects that are difficult to detect, such as strongly reflective parts or multi-colored labels. The Inspector product family offers extensive support in controlling, monitoring, and data collection thanks to numerous interfaces. A multitude of new ice-cream varieties are launched on the market annually. This increase also leads to a greater diversity of folding box designs. For instance, now there is the new Magnum box with rounded edges and its exclusive eye-catching design, for as everyone knows you first eat with your eyes.The HK 4 horizontal cartoner ensures error-free packaging of different ice-cream batches and assortments in diverse folding box designs. Nothing stands in the way now of the sensory check at the end of the value chain - that is to say, when the ice-cream lover gets to taste the ice cream. There is no accounting for taste as they say. Unless its the wrong one...

- Product information: Lector620 Professional image-based code reader

- Product portfolio: Image based code readers , 2D-Vision Sensors