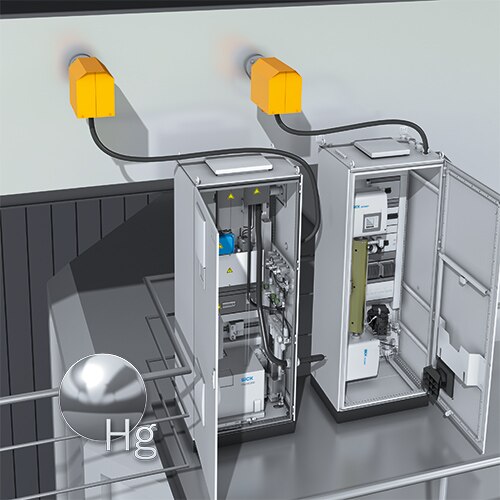

SICK gives operators of waste incineration plants certainty with rugged measurement technology and rapid measurement results. The MCS300P HW analyzer solution measures sulfur dioxide and hydrochloric acid while the MERCEM300Z is specially designed to measure mercury. Both systems are ideal for optimizing processes in waste incineration plants.

Waste incineration makes it possible to generate thermal and electrical energy. However, the pollutants released by the combustion process must be minimized as far as possible. Without efficient and state-of-the-art gas cleaning equipment, it’s virtually impossible to reduce the high concentrations of hydrochloric acid, sulfur dioxide and mercury in untreatedgas to the required limits. And yet, what’s the use of even the best cleaning plant if it can’t precisely detect gas concentrations or display them rapidly enough? The MCS300P HW and MERCEM300Z analyzer systems from SICK supply measured values that enable plant operators to quickly initiate the necessary process regulation measures as well as to regulate the exhaust gas cleaning.

Rapid measurement results also make it possible to respond appropriately to sudden peaks, which support efforts to comply completely with the current emission limits. In the European Union, the measurement of industrial emissions is governed by the Industrial Emissions Directive (IED) 2010/75/EU – formerly the Waste Incineration Directive (WID) 2000/76/EC. Thanks to the upcoming revised BREFs (Best Available Technique Reference Documents) for waste incineration plants with the list of BAT-AELS (Best Available Technique – Associated Emission Levels), this Directive applies across the EU and must be implemented accordingly by all EU member states.

Potential savings are in the air

Indeed, acidic gas components must be removed from gas mixtures. To achieve this goal, it’s one thing to know the exact concentration of hydrochloric acid and sulfur dioxide and it’s another thing to reduce the quantity of consumables for the cleaning process. Most often, excessive amounts of chemicals are used in this cleaning process in order to keep emissions within the prescribed limits. In fact, exact and rapid gas concentration measurement additionally allows operators to save money. Precise and rapid measuring makes it possible to use only the quantity of chemicals that‘s actually necessary in the cleaning process.

Indeed, acidic gas components must be removed from gas mixtures. To achieve this goal, it’s one thing to know the exact concentration of hydrochloric acid and sulfur dioxide and it’s another thing to reduce the quantity of consumables for the cleaning process. Most often, excessive amounts of chemicals are used in this cleaning process in order to keep emissions within the prescribed limits. In fact, exact and rapid gas concentration measurement additionally allows operators to save money. Precise and rapid measuring makes it possible to use only the quantity of chemicals that‘s actually necessary in the cleaning process.

In most cases, once adjusted in light of this vital information, chemical consumption itself can be reduced, which also reduces the quantity of used adsorbents to be disposed of, while additionally providing significant cost savings. With a mere 10% reduction in adsorbents, the capital investment for the MCS300P HW is amortized in just one to two years.

Additional advantages: the MCS300P HW measures HCl, SO2 and H2O simultaneously; as well as other gas components if desired, e.g. CO, NO and O2. With heated gas extraction (above the acid’s dew point) and very high gas flow, response times of approximately 30 seconds are realistic. The exhaust gas is extracted without passing through a cooler and passes directly into the heated gas measuring cell. A special blowback function ensures that the coarse filter at the sample probe is automatically cleaned. The entire system is corrosion- resistant. Modern, digital communication interfaces support optimal data transparency while maintenance costs remain low thanks to remote maintenance.

Mercury in untreated gas

Compared to emission measurement, mercury measurement upstream of the electrostatic filter or scrubber is significantly more demanding – with higher dust loads and higher concentrations of interfering components like sulfur dioxide and hydrogen chloride. Even the Hg concentrations might be detected up to the mg/Nm³ range. Dropping activated carbon upstream of the electrostatic filter or scrubber adsorbents eliminate mercury out of the process gas. Although the addition of these chemical auxiliary agents is expensive, excessive quantities of both are often used due to intransparent information of the actual existing Hg concentrations in the untreatedgas. Costs can be reduced as well, if the plant operator uses the correct quantity of

Compared to emission measurement, mercury measurement upstream of the electrostatic filter or scrubber is significantly more demanding – with higher dust loads and higher concentrations of interfering components like sulfur dioxide and hydrogen chloride. Even the Hg concentrations might be detected up to the mg/Nm³ range. Dropping activated carbon upstream of the electrostatic filter or scrubber adsorbents eliminate mercury out of the process gas. Although the addition of these chemical auxiliary agents is expensive, excessive quantities of both are often used due to intransparent information of the actual existing Hg concentrations in the untreatedgas. Costs can be reduced as well, if the plant operator uses the correct quantity of

Ideal for this application, the MERCEM300Z supplies rapid and reliable measured values. Furthermore, excessive mercury concentrations in the process can cause a long-term contamination of the entire plant. In the worst-case scenario, the plant may face downtime.

Additional advantages: the MERCEM300Z is designed especially for monitoring total mercury emissions in flue gases, which can be measured both in untreatedgas as well as purified gas. The system meets all current and currently known future limits and requirements. Continuous measurement with simultaneous conversion of oxidized Hg at 1,000 °C in the gas measurement cell in combination with Zeeman atomic absorption spectroscopy (AAS) is patented and licensed exclusively for use in the MERCEM300Z by SICK. This technology also ensures that measurement performance is not disturbed by interfering components like SO2. SICK’s popular operating concept and the modern communication protocols are the perfect finishing touches to the MERCEM300Z’s profile, making it a sophisticated mercury measurement system that is easy to integrate and stable on a long term basis.

Energy. Efficiency. Transparency: Achieving more with SICK

Related posts:

FLOWgate™: The gate to ultrasonic gas flow measuring devices from SICK

Custody transfer gas measurement: Modernization of the SGI gas pipeline interconnection point

Smart: sensors control garbage disposal