Renewable energies, especially from wind, water, or sun, are playing an increasingly important role in the decarbonization of the energy supply. Although natural gas will remain an important energy source for maintaining a stable and affordable energy supply for many years to come, the search for alternatives has long focused on hydrogen as an additional energy source. And energy storage is also becoming increasingly important: not only in order to come closer to the goal of a CO2-neutral energy supply, but also on account of the intermittent and in particular weather-dependent energy generation on the one hand, and seasonally fluctuating consumption on the other.

Measurement of hydrogen and hydrogen-enriched natural gas using ultrasonic flow meters

Hydrogen in the gas network

The production of hydrogen from renewable energies and the feeding in of the hydrogen into existing gas networks play an important role on the way to a CO2-neutral energy supply. Hydrogen can be produced in locations where there is a high availability of renewable energy. Furthermore, it can be stored and transported to the consumer as an additional energy carrier via the existing gas networks. Hydrogen can be stored and transported at up to 30 vol.% in the existing natural gas distribution network.

The networks for pure hydrogen will initially be expanded regionally. These will then gradually grow together to eventually form larger networks. Estimates for a Europe-wide hydrogen transport network predict that up to 40,000 km of network can be created by 2040.

Effects on gas flow measurement

The ability to reliably and stably measure the flow of natural gas with admixed hydrogen is therefore becoming increasingly important these days. The change in gas composition poses new measurement challenges for the various metering technologies. This is because the added hydrogen affects the properties of the natural gas: the density, viscosity, explosivity, flow rate, and sound velocities of the gas change. This poses completely new challenges for pipelines, compressors, seals, valves, measurement technology, etc., for example in regard to the risk of leaks and explosions or the determination of the calorific value. Gas network operators and gas suppliers are therefore wondering how this will affect the performance of their gas flow meters.

Ultrasonic flow measurement has set a new standard for reliability, durability, and measurement accuracy in both the natural gas and process gas industries over the past two decades.

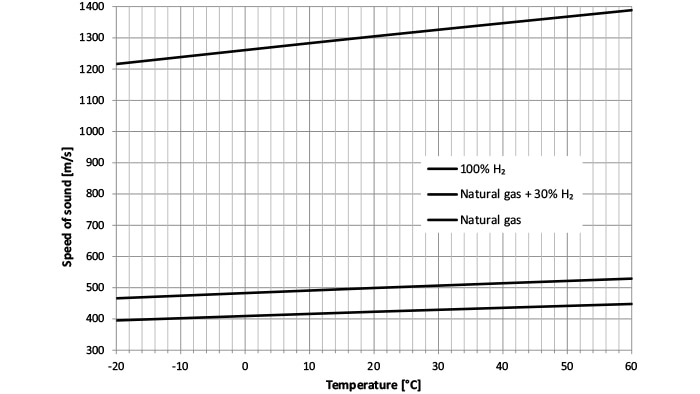

Adding a small percentage of hydrogen to natural gas already significantly increases the speed of sound (SOS) of the gas mixture. At 100% hydrogen by volume, it is about three times that of natural gas. The diagrams in Figure 1 show the SOS for natural gas, a hydrogen mixture of 30 vol%, and pure hydrogen.

This places several requirements on the USM design. Both the natural gas-equivalent measuring range and the required measurement uncertainty must be ensured. This includes reducing the scatter of measured values, reducing cross-sensitivities to pressure, temperature and media fluctuations, and reducing fluid-mechanical effects.

For natural gas with hydrogen admixtures of up to 30 vol%, it is still possible to compensate for this effect.

Ultrasonic flow measurement: Ready for future requirements as well

The same specifications and requirements - especially with regard to measurement accuracy - can be expected for the future custody transfer measurement of hydrogen admixtures and pure hydrogen as for measurement in natural gas. The ultrasonic gas flow meters (USM) must be appropriately adapted to the new measuring task.

Dedicated hydrogen transport pipelines will not differ significantly, however, from natural gas pipelines. The requirements are similar to those for today's natural gas meters. For an energy-equivalent transport capacity, either larger nominal diameters or higher flow rates are required in the transport systems. USMs specially designed for hydrogen must therefore permit higher maximum gas velocities.

As USMs can satisfy all the requirements very well, they are ideal for custody transfer flow measurement in future transport and distribution networks, whether for hydrogen admixtures or pure hydrogen.

The advantages of flow measurement using a USM are:

- Wide range of nominal diameters (DN50 to DN1400)

- High measuring span of ≥ 1:100

- Non-blocking, no pressure loss

- No mechanical moving parts, no pulsation

- Higher flow rates with hydrogen

- Transferability of the calibration to other media

In addition to classification according to hydrogen content, USMs can also be differentiated according to their use in process gas applications, in transport networks, and in distribution networks:

A. Process gas measurement

USMs have been used for many years in process gas plants for measuring gases with different hydrogen contents. They differ from standard measuring equipment designed for custody transfer measurements due to their limitations with regard to measuring gases with higher hydrogen content. This affects the inlet conditions, the achievable measurement uncertainty, and the flow and pressure range limitations. With the development of new ultrasonic sensors for use in pure hydrogen, the previous limitations compared to standard meters should no longer apply for these applications as well.

B. Measurement of hydrogen-containing gases in transport networks

In transport networks, large quantities of gas are transported in pipelines with a minimum nominal diameter of DN400 and at high pressures. The latest generation of gas flow meters, for example, the FLOWSIC600-XT, can also measure gases with a hydrogen content of up to 30% by volume and are approved for custody transfer volume measurement. The prerequisite for this is that the reliability and quality of the measurement results are not or only insignificantly affected by changes in density, flow velocity and SOS.

C. Measurement of hydrogen-containing gases in distribution networks

USMs in distribution networks differ with regard to their design pressure (typically < 20 bar) and nominal diameter (≤ DN150). The FLOWSIC500 is specially designed for use in natural gas distribution. It has been qualified for measuring up to 30% hydrogen by volume over the entire specification range by modifying the signal evaluation and extending the measurable SOS range.

Gas Quality Indicator (GQI): Determination of the hydrogen content

In addition to the primary measured values and the required high accuracy, ultrasonic gas flow meters (USM) offer further advantages: Thanks to the implementation of a “gas quality indicator” (GQI) in the USM, this device offers the ability to detect changes in the gas composition via the value of the speed of sound (SOS). Even small changes in hydrogen content can be detected very accurately due to the extremely high SOS of hydrogen. If the reference gas composition or its SOS (without hydrogen) is known, it is also possible to very accurately determine the hydrogen content. The device compares the measured SOS value with the reference SOS value. Assuming that any difference is solely attributable to the hydrogen admixture, the hydrogen content can be determined directly. The approximation is done via an empirical formula implemented in the firmware of the USM.

The picture below shows an example of a FLOWSIC500 USM in the mixing station of the “Hydrogen in the gas network” pilot project in the Fläming region, Saxony-Anhalt, Germany. This communal project will add hydrogen admixtures of up to 20% by volume to the natural gas distribution network. The meter is used to measure the volume of the natural gas/hydrogen mixture. At the same time, the hydrogen content of the natural gas is measured by means of the GQI.

Summary

Ultrasonic gas flow meters have been successfully used for more than 20 years to measure the quantity of gas in a wide range of applications. This includes applications for gases with different hydrogen contents. The devices used in these applications, as well as others from the SICK FLOWSIC product family, have already been adapted and approved for the fiscal metering of natural gases with a hydrogen content of up to 30% by volume. Operators of gas networks can follow the trend of feeding regenerative produced hydrogen into existing gas networks, and transporting and storing the hydrogen - without additional investment in new gas flow meters.

The diagnostic options of the USM allow not only a quantitative measurement but also a qualitative determination of the gas. The device therefore provides a supplementary analysis method for hydrogen. This can replace costly analytical techniques for hydrogen determination, such as extractive gas chromatography, in some applications.

For already installed devices, an inspection of the device condition is recommended to evaluate the impact of feeding in up to 30% hydrogen. The effect of aging, installation conditions, or the pressure regulator should also be checked. The Service department at SICK can assist with this evaluation.