Decarbonization of the mining industry on the path to a sustainable future

To ensure a more environmentally friendly and sustainable extraction and processing of raw materials, mining companies are taking significant steps to reduce their environmental impact.

The most important strategies include:

- Improving the energy efficiency

- Electrifying the vehicles and machines

- Using alternative fuels

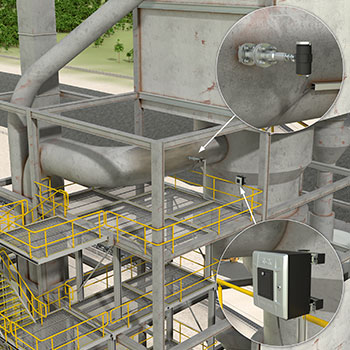

- Optimizing processes

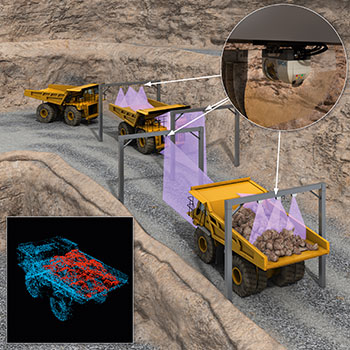

- Using automation solutions

- Integrating themselves into the upstream and downstream supply chain

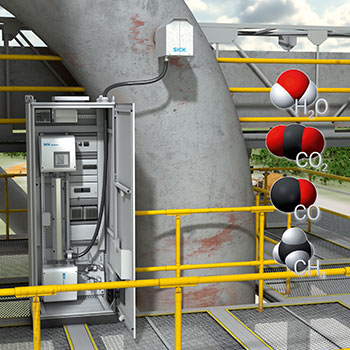

Mining companies are pursuing a holistic approach and implementing measures to reduce emissions in every phase of their business. This includes direct emissions from their mining operations, indirect emissions from purchased energy, and emissions along the entire value chain.

Mining 4.0 plays an important role in this context, whereby 75% of companies will have retrofitted their important machines and vehicles with intelligent sensors by 2027. The digital transformation in the mining sector means more safety, higher productivity, more efficiency and profitability, as well as a more sustainable operation.

Improving the energy efficiency

Energy efficiency is one of the most important drivers for decarbonization. Investment in advanced technologies and better methods for minimizing energy consumption and reducing greenhouse gas emissions are essential. By optimizing processes and using more energy efficient equipment such as high efficiency motors, batteries and intelligent control systems, companies are achieving significant energy savings and reducing their carbon footprint.