The Ranger3 streaming camera is setting the future standard for industrial 3D image processing in regards to technology, speed, resolution, and ease of integration. With its innovative ROCC technology (rapid-on-chip-calculations) developed by SICK, it can process up to 15.4 gigapixels per second, enabling full-frame 3D imaging (2,560 x 832 pixels) at a speed of 7 kHz. As a result, the Ranger3 3D vision camera is capable of taking high-resolution 3D measurements of dimensions, contours, and surface properties even in rapid production and inspection processes in order to detect the most minute deviations and faults. The contour detection of the laser line, which is projected onto the object, takes place regardless of color and contrast, from the ambient brightness or – as is the case for IMS Messsysteme – from the visual appearance of profiles, slabs, or pipes flickering with heat.

IMS Messsysteme: Market leaders for optical inspections in the steel, aluminum, and metal industry

IMS Messsysteme GmbH in Heiligenhaus develops and produces isotope, X-ray, and optical measurement systems for industrial applications in the steel and non-ferrous-metals industry. Founded in 1980, the company now employs around 450 employees across five continents. “We have asserted ourselves as the technological and market leaders in continuous casting plants, hot rolling mills and tube rolling mills with complete solutions such as the X-3Dvision measurement system,” explains Dipl.-Ing. Zvezdan Pejovic, Product and Sales Manager for optical 3D inspection systems at IMS. In just a single step, the systems are capable of checking long-goods profiles and pipes in terms of their dimensions, contours, and linearity, as well as for surface defects such as cracks, deposits, inclusions, or indentations – even under the harshest conditions. “The earlier faults are detected, the quicker it is to correct machining processes and avoid rejects,” explains Zvezdan Pejovic. “This is why our measurement systems are even used as far upstream as the thermal production process. The temperatures of the profiles and pipes are still almost 1000 °C here, which places huge demands not only on the measurement technology itself, but also on the mechanical structure of the measurement systems.”

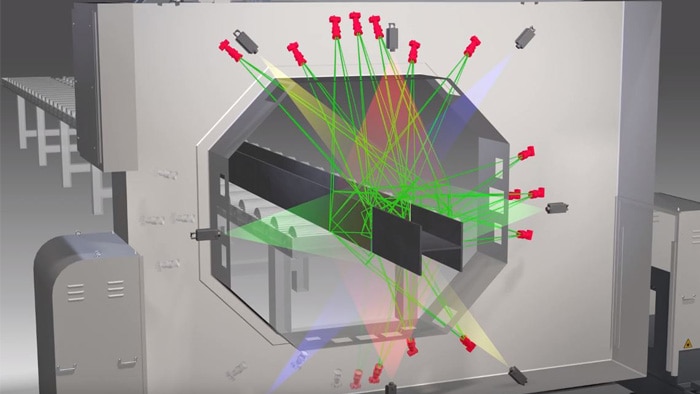

The X-3Dvision measurement systems from IMS are used for 360° inspection of products with a wide range of geometric properties. “In order to capture the entire surface of profiles or pipes seamlessly, we integrate multiple cameras and laser lighting devices into a single, circular measurement setup through which the long goods are passed for inspection – and that’s basically all there is to it,” clarifies Zvezdan Pejovic. “The metrological components are integrated into the robust frame construction where they are protected against direct contact with the harsh surrounding environment. In addition, the cameras and laser transmitters are cooled by air and water to ensure stable ambient temperatures for precise and reproducible measurement results.” Precision is one of the real strengths of the IMS measurement systems. When it comes to contour measurements, the company offers a typical resolution of 0.05 mm and repeatability of ± 0.08 mm. As for surface inspections, furrows, cracks and scratches measuring as little as 0.3 mm wide, 10 mm long, and 0.3 mm deep can be measured and detected reliably (for example: in an existing installation downstream of the stretch-reducing mill, based on a production speed of 10 m/s). Both the dimensional and contour measurement as well as the inspection of the surfaces can therefore be carried out with a specified level of accuracy and repeatability down to the submillimeter range, ensuring products are always manufactured to the highest quality.