scanware electronic GmbH in Bickenbach, Germany, develops and manufactures inspection systems for the 3D quality control of pharmaceutical products during the packing process. Nowadays, 2D cameras are no longer up to the inspection tasks set by packaging machine manufacturers and pharmaceutical companies. Thats why, for ten years now, scanware has relied on the high-resolution, versatile Ranger 3D vision camera from SICK when it comes to developing custom solutions. The extremely high speed during the transmission of the line profiles can even keep up with especially fast-paced packaging machines - meaning that quality doesnt fall by the wayside.

Since as early as 2006, responding to a customer request, scanware had been searching for a solution that could ensure that blister packages were filled correctly. It was a matter of ensuring the quality of sealed aluminum blisters. Guaranteeing the quality of the product meant detecting the smallest of deformations in the aluminum that occur during the transport process in the machine, said Harald Mätzig, Managing Director of scanware, looking back. Possible solutions to this task were trialed using grayscale and color cameras in combination with a wide variety of Illumination techniques - but to no avail. We were looking for a product to be used on a very fast packaging machine. It had to have a high processing speed as well as a high resolution, said Mätzig. It was at the Vision 2006 trade fair that we discovered SICKs Ranger streaming camera that we then tested. Our trials were a success and in 2007 we installed the Ranger on a packaging machine that was ultimately used in production for quality control purposes.

3D monitoring for tablets, capsules, and small power quantities

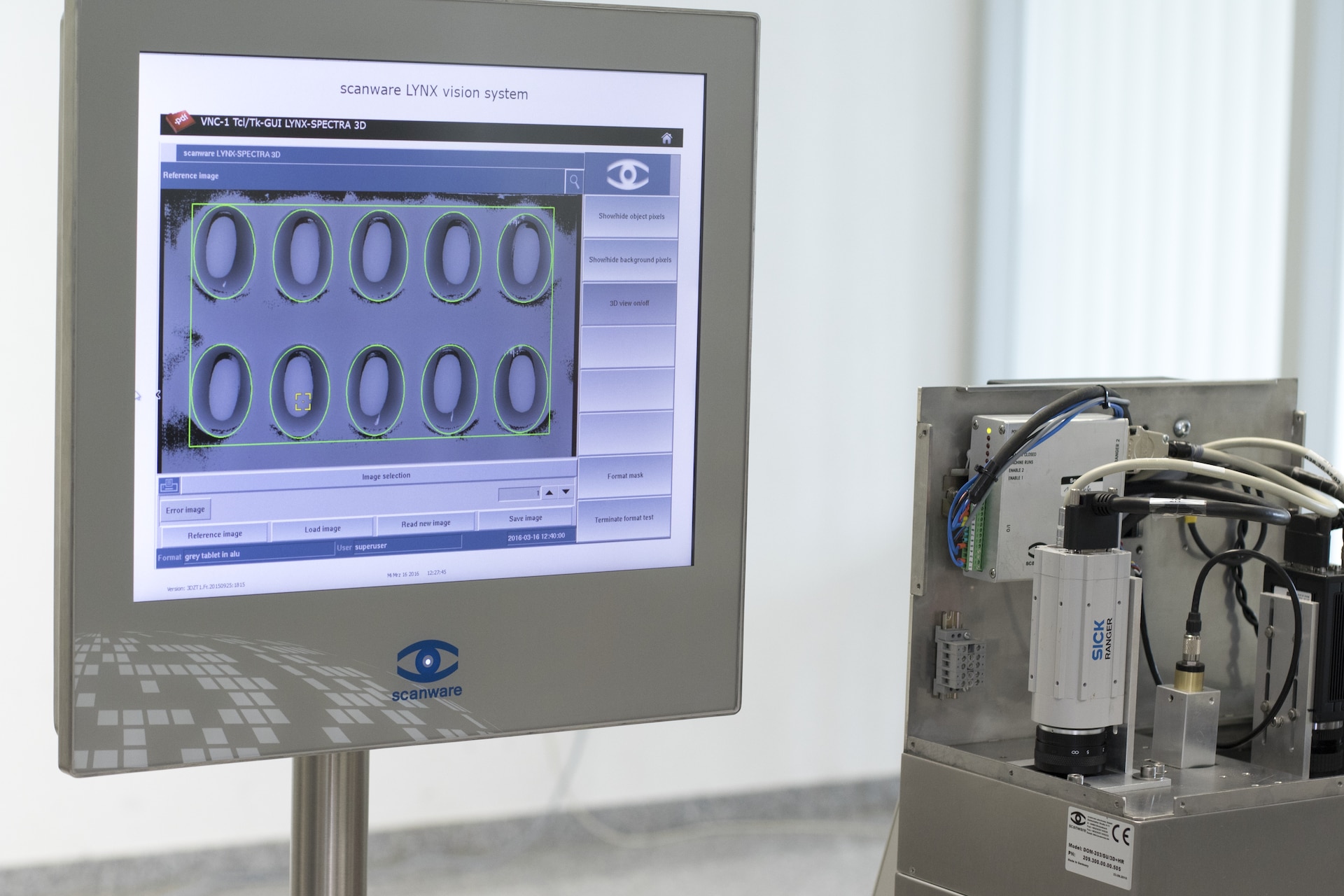

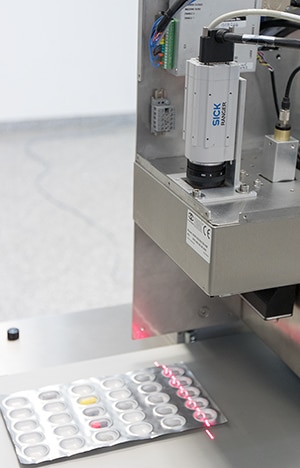

From 2008, the scanware team began to further develop the existing LYNXSPECTRA CL/HR image processing systems on the basis of color product inspection. The result was the LYNX-SPECTRA 3D system: a high-resolution, laser-based image processing system for the 3D monitoring of foil, tablet, and capsule geometry for undesirable deformations of any kind, such as dents, bulges, or spalling. Dominik Hüfner, System Developer at scanware, explains: The scanware 3D system consists of a color part and a 3D part with a Ranger streaming camera from SICK to check products in terms of color, shape, and volume. The standard Ranger configuration was an X/Y/Z resolution of ~0.1 mm/pixel at a conveyor speed of up to 1.5 m/s. This camera allows us to generate very high-quality 3D data at a very high speed, said Hüfner. It opens up a whole new set of possibilities for monitoring product characteristics that are not easy to detect with a 2D camera. Firstly, additional height monitoring ensures the reliable detection of defects in products and packaging. For example, if tablets are standing up on end, they may break through the sealing foil during the sealing process, meaning that the blister is not completely sealed. Or if tables have broken apart in the middle and only half is in the blister. Now Ranger has made it possible to reliably detect defects like this in terms of height and volume. As a result of this, we are also able to remove defective products and packaging from production. The scanware system is even suitable for monitoring a dosed volume of small powder quantities in aluminum blister strips.

Integration and adaptation to custom applications

Expanding the pre-existing LYNX-SPECTRA CL/HR color systems with the Ranger streaming camera was not done without mechanical and electrical challenges.  For example, the results of the camera had to be linked to the color system and transmitted to the machine. Whats more, the Ranger camera had to be integrated into existing and new packaging machines from a variety of manufacturers. As a result, the camera was completely implemented under the QNX real-time operating system. The 3D image is generated using a laser triangulation process. The image-recording geometry for the laser triangulation process was built into a scanware illumination unit, with the laser units being able to be reduced in size thanks to mirror deflection. Using the Ranger requires a frame grabber and a multicamera switcher board that supports line-oriented image transmission. As all analysis algorithms were developed inhouse, a higher degree of flexibility could be achieved when adapting the system to custom applications, while still ensuring maximum performance.

For example, the results of the camera had to be linked to the color system and transmitted to the machine. Whats more, the Ranger camera had to be integrated into existing and new packaging machines from a variety of manufacturers. As a result, the camera was completely implemented under the QNX real-time operating system. The 3D image is generated using a laser triangulation process. The image-recording geometry for the laser triangulation process was built into a scanware illumination unit, with the laser units being able to be reduced in size thanks to mirror deflection. Using the Ranger requires a frame grabber and a multicamera switcher board that supports line-oriented image transmission. As all analysis algorithms were developed inhouse, a higher degree of flexibility could be achieved when adapting the system to custom applications, while still ensuring maximum performance.

Easy operability, maximum safety, and a wide range of applications

The scanware LYNX-SPECTRA 3D system featuring the SICK Ranger streaming camera is easy to operate thanks to its user interface that corresponds to the standardized menu structure of all scanware systems. The scanware image processing library has been expanded with 3D analysis algorithms. In order to provide a better understanding of the analysis results, the system is equipped with 3D visualization. The system is certified to laser class 1, meaning that it offers maximum safety for the user. The Ranger camera features the unique MultiScan function that facilitates the simultaneous measurement of a multitude of other object characteristics, such as contrast, gloss, and laser scattering. As a result, Ranger boasts better detection capabilities for low-contrast objects, such as gray on aluminum. The provision of all information from just one single Ranger camera enables safe decisions and cost-efficient solutions. Harald Mätzig states: Our experiences with the Ranger camera from a wide range of requirements with regard to speed and resolution mean that we can now offer a broad spectrum of customer applications. Building on the many years of positive experiences that scanware has had with the Ranger streaming camera from SICK, the new LYNX-SPECTRA 3D color system type - which makes pixel-precise combination of 3D and color data in a single system possible - is set to hit the market in the near future. This system uses the ColorRanger E50 3D camera from SICK.

ColorRanger allows us to overlay 3D data and color data with pixel precision and therefore evaluate color and 3D in a single passage, explains Dominik Hüfner. In particular, reducing the size enables better integration on small machines and systems. As we are able to significantly reduce the size, we gain additional opportunities to make custom systems even more compact, as color and 3D can now be installed in a single housing.

- Product informationen: Ranger E50

- Product portfolio: 3D vision