Creative ideas and practicable solutions are necessary to meet this increasing demand for human-robot collaboration. The advantages of a classic industrial robot cell, such as speed, accuracy, high productivity and durability, should by no means be neglected. The robot’s payload also plays an important part, but is very limited in existing human-robot collaborations.

Collaborative robots cannot serve these high demands of industry, as they work at significantly lower speeds and with lower payloads than industrial robots. The limits also quickly become apparent in the area of connectivity and integration options in existing systems. For this reason, KUKA, together with SICK and Blue Danube Robotics, is now offering a complete solution that combines both maximum productivity and the latest safety standards for collaborative applications. First and foremost, safe collaboration between robots and humans is guaranteed, even with payloads of several 100 kg. Smooth interaction between all components is made possible by the robot controller and the KUKA.SafeOperation technology package.

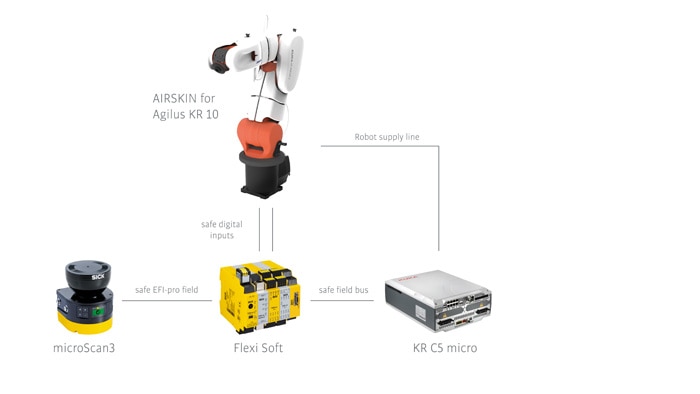

An application in which components are assembled manually and then a visual inspection is carried out by the robot serves as an example application. The robot cell can be designed without a safety fence and it is possible to approach the robot or work directly with it at any time. The dangers of this close teamwork are reliably safeguarded by the microScan3 safety laser scanner from SICK – and therefore enable both safe and efficient collaboration between humans and robots.

sBot Speed CIP safety system

The sBot Speed CIP system variant for KUKA from SICK combines a microScan3 with the Flexi Soft safety controller and the EFI-pro gateway. The robot-specific settings and communication parameters are already pre-configured and can be integrated quickly and safely into the KUKA KR C4 robot controller thanks to EtherNet/IP™ CIP Safety™. This saves valuable time in project planning and evaluating the safety concept.