Ultrasonic sensors perform measurement and detection tasks in a wide variety of application areas on colored, shiny, or transparent surfaces, which are particularly challenging for optical sensors. Even adverse ambient conditions such as dust, dirt, or fog hardly affect the measurement result. The broad detection range also allows for a large field to be monitored with just one sensor – with a measuring range of 13 mm to 8 m.

Ultrasonic sensors - Functionality and areas of application

Functionality ultrasonic sensor

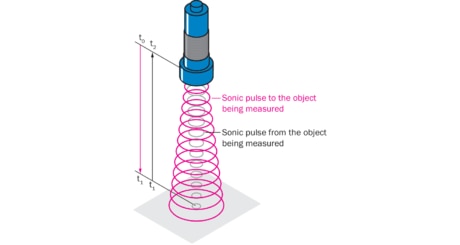

(Acoustic) time-of-flight measurement

The sensor emits an acoustic pulse that is reflected by the object being detected. The time required for the pulse to go from the sensor to the object and come back again is measured, evaluated and converted into the distance as follows.

Distance = speed of sound x total acoustic time of flight (t2) / 2

Scanning range of ultrasonic sensors

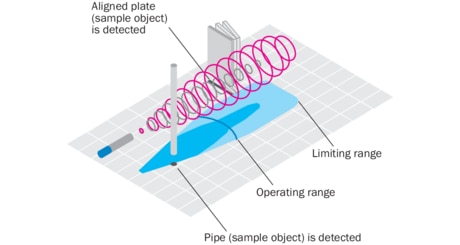

In general on ultrasonic sensors, the less sound the object being measured absorbs, the greater the possible scanning range. The operating range specifies the distance up to which measurement on common objects with sufficient operating reserves is possible. Under ideal conditions, the sensor can even be used up to its limiting range. Switch panels are used for ideal assessment of application capability. The dark blue area shown in these switch panels shows an example of the sensor's working range if a round rod is detected. The light blue area shows the maximum detection range (limiting range) which can be achieved under ideal conditions for easily detectable objects, such as the aligned plate given here. This area between the sensor and the measuring object should be kept free of other objects to prevent them from being detected accidentally. The detectability and detection range of an object depend on its reflective properties, size, and alignment. Depending on the application, the sensor may also be able to detect very small objects, e.g. metal wire.

Fields of applications

Ultrasonic sensors can be used in a wide variety of applications. For example, in the diameter control of a material roll for winding and unwinding a wide variety of materials, process monitoring is used to increase the reliability of the system. In the next process step, material tracking can be adjusted by monitoring the sag depth of the material, which also increases process quality. In process and quality control, ultrasonic sensors can help detect incorrectly or incompletely produced goods as well as unwanted alignments. This reduces plant downtime and ensures maximum productivity. Mutliplexing of multiple sensors makes it possible to determine the dimensions of, for example, packages on a conveyor belt. Area monitoring can be realized with the help of synchronization of several ultrasonic sensors.

Measurement of double layers and glued joints

The ultrasonic inspection of double layers and glued joints is the UD18's specialty.

It precisely detects whether there is one, two or no sheet of material between its transmitter and receiver. The UD18 shows its full strength in double-layer inspection of paper, cardboard, shiny metal and transparent plastic.

The sender sends ultrasonic waves towards the receiver. If there is no material between the sender and receiver, the ultrasonic waves arrive at the receiver at full strength. If there are one or two material layers between the sender and receiver, the ultrasonic waves are correspondingly weakened. The receiver directly evaluates the respective ultrasonic pulse and sets the corresponding output signals.

Possibilities for difficult measuring conditions

If the space for installation the sensor is very limited, the use of a baffle plate can be useful. This baffle is ideally positioned in the blind zone of the sensor. Furthermore, by deflecting the sound downwards, aggressive chemical outgassing can be kept away from the sensor head and its service life is increased. If the sound is deflected upwards, deposits on the sensor head can be avoided, e.g. in dirty, oily or humid environments. This contributes to optimal measurement and detection. To increase the measuring range with the help of several ultrasonic sensors use the possibility of synchronization or multiplexing of the sensors. In the synchronization mode, all connected sensors send the sound pulse at the same time and also receive it at the same time. This leads to a larger measuring range and enables the detection of objects at any point within the measuring range.

Multiplexing of several sensors

Another possibility is the multiplexing of several sensors. The sensors are connected in series for sending and receiving. Only when sensor 1 has sent and received, sensor 2 sends and receives and so on. In this operating mode, mutual interference of the sensors is completely avoided, but the total response time is reduced.

Read more

FLOWSIC150 careflow directly measures the exhaust gas volume flow. With ultrasonics.

I want to stay up to date and regularly be informed about new articles!