Navigating through extensive manuals and documents while configuring sensors poses a significant challenge for operators in various applications. The complexity increases as different photoelectric sensors cater to diverse applications and use cases, demanding a substantial amount of knowledge.

Tackling challenges in the setup of photoelectric sensors

Say goodbye to the hassle of complex configurations with the introduction of the latest all-in-one photoelectric sensor. This W10 includes the world’s first photoelectric sensor with an intuitive touchscreen interface, streamlining the configuration process to a single sensor. Even within the realm of photoelectric sensors, the integration of a touchscreen, exemplified by the new W10, presents an opportunity for enhanced user benefits.

Let's explore some common challenges associated with the manual setup of photoelectric sensors, and how the touchscreen configuration option with the W10 can alleviate these pain points.

What is involved in the configuration process?

Key parameters that might be adjusted during configuration include sensing distance, sensitivity, response time, operating mode, switching output, and alignment.

Operators typically refer to the sensor's user manual or documentation provided by the manufacturer to understand the specific configuration parameters and recommended settings for their application. While this gives operating entities control over the sensor's behavior, it can be prone to challenges such as human error, inconsistency, and the need for frequent adjustments.

Overcoming these common challenges with a touchscreen sensor

Human error and time

Typical configuration involves setting parameters such as sensing distance, sensitivity, and other settings. Human error during this process can lead to inaccurate sensor settings, resulting in improper detection or false alarms.

On top of that, different individuals may configure sensors differently, leading to inconsistency in the setup. Inconsistency can affect the overall reliability of the sensor network within a manufacturing environment.

Probably the biggest pain point with a more complex configuration is that it’s a time-consuming process, especially in large manufacturing setups with numerous sensors. It may require considerable time and effort to configure each sensor individually.

With the W10, configurations such as foreground and background suppression can be selected via the intuitive touch display to boost detection quality. In addition to the common 1-point teach, which detects objects at a defined distance, a 2-point teach allows objects of different heights to be detected without increasing the risk of detection errors. A manual mode extends the teach options and provides high flexibility.

Security and location of the photoelectric sensor

In industrial settings where sensors are installed in challenging or hard-to-reach locations, many configurations can be impractical. Accessing sensors in such locations for adjustments may be challenging. This is where a touchscreen application comes in handy because it becomes easier to configure the sensor.

In some cases, sensor adjustments may be vulnerable to tampering or unintentional changes by unauthorized personnel. This can lead to disruptions in the manufacturing process. Manufacturing environments may experience variations in conditions such as lighting, temperature, or the type of materials being processed.

Security is paramount in industrial settings, and the W10 addresses this concern with its button-free interface and lockout ability. By eliminating physical buttons, the W10 minimizes the risk of unwanted in-field changes, ensuring that your settings remain consistent and secure. The lockout ability adds an extra layer of protection, giving users peace of mind regarding the integrity of sensor configurations.

On top of this level of security, you can feel confident that the W10 is built to last. With an IP69K rating, the sensor is built for harsh environments, meeting or exceeding many commercially available sensors today.

W10 – the solution to complex configuration

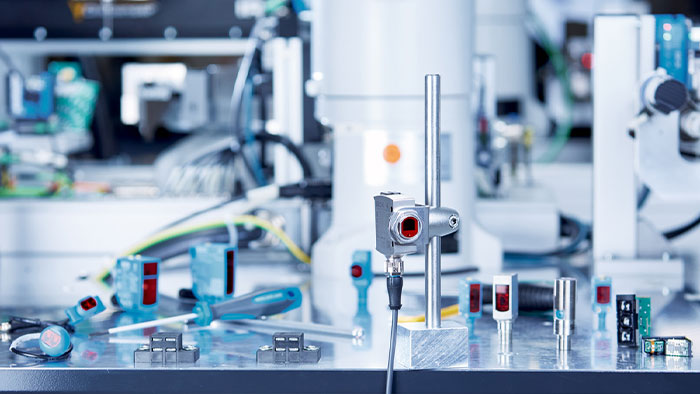

In a move toward efficiency, SICK has introduced the "one for all" concept with the W10. For all applications, the W10 combines range, speed, resolution, precision, and robustness in a one for all sensor concept with different modes.

This concept also allows for a significant reduction in part numbers and a simplified approach to applications. The W10 is an all-round solution which offers unparalleled flexibility. A single sensor can be put into stock instead of many different ones with similar properties.

With just one part to order, manage, train on, troubleshoot, and service, the W10 redefines the expectations for streamlined operations in the industrial sector. This not only reduces the burden on procurement and inventory management, but also ensures that training and maintenance become a seamless process.